舒利工业木材剥皮机如何帮助瑞士锯木厂!

瑞士以其严苛的工业标准和高质量的木材加工闻名,当地的木制品制造行业强调环保和精度。

这位瑞士客户是中型木材加工企业的负责人,主要从事建筑用木材和木制品制造。为了提升原木预处理效率,他决定采购一台高性能工业原木去皮机,用于去除树皮并提高后续锯切和刨平的精度。

如何达成合作?

根据客户的原木直径范围(12–42厘米)和生产要求,Shuliy机械推荐了SL-460 原木去皮机。

- 型号:SL-460

- 容量:240立方米/小时

- 适用于原木直径:12–42厘米

- 尺寸:2.7*2*2.45米

- 重量:2470公斤

该型号通过采用变频调速送料系统,消除了传统的动力限制,实现了更稳定、更平滑的原木送料和卸料操作。其加工能力高达240立方米/小时,满足客户的大批量处理需求。

此外,为确保长期稳定运行,客户订购了4套备用刀片(共20片刀片)和8个压力弹簧,以及刀片弹簧总成,方便未来维护和更换。

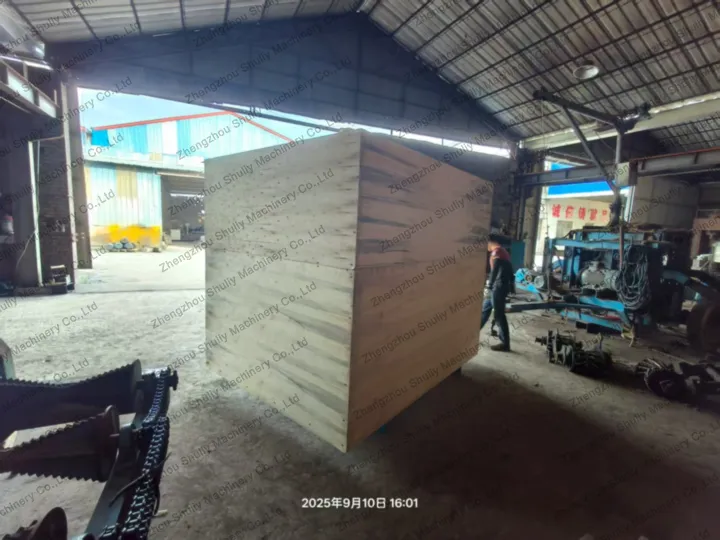

根据协议,Shuliy机械立即出具正式的形式发票,详细列明设备、备件以及包装和运输的费用。木材剥皮设备享有12个月的保修。付款方式为30%订金,余款在发货前结清。

客户的反馈意见

设备到达瑞士后,客户在当地工厂完成了安装调试。他们对Shuliy工业原木去皮机的性能表示高度满意。

客户特别称赞:

“实现了干净去皮、高效率、低噪音和简便维护,显著提升了生产线效率。”