Máquina peladora de corteza de madera y aserradero para aserradero de madera en Malasia

Este cliente de Malasia opera una planta local de procesamiento de madera, especializada en el procesamiento primario de troncos. Con la expansión del negocio, el cliente desea introducir máquinas de pelado de corteza de madera y aserraderos más eficientes y estables, y aumentar la capacidad de procesamiento de troncos para satisfacer más pedidos.

Por lo tanto, el cliente decidió comprar peladoras de troncos y serrerías de alto rendimiento para las operaciones de preprocesamiento y corte de madera del aserradero.

Solución recomendada por Shuliy

De acuerdo con las condiciones de trabajo reales del cliente y el tipo de madera que se va a procesar, Shuliy recomienda la máquina peladora de corteza de madera modelo SL-320 y el aserradero vertical modelo SL-50:

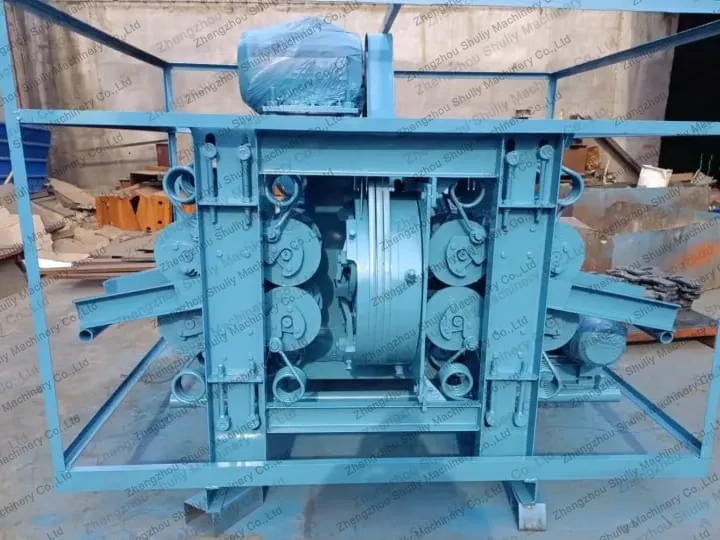

Máquina de desmonte de madera SL-320:

La potencia es de 7.5kw+2.2kw, el voltaje es de 415V, 50Hz, electricidad trifásica, y puede manejar troncos con un diámetro de 10-30cm. El equipo tiene un tamaño razonable, ocupa un área pequeña y es adecuado para su instalación en la línea de ensamblaje de un aserradero.

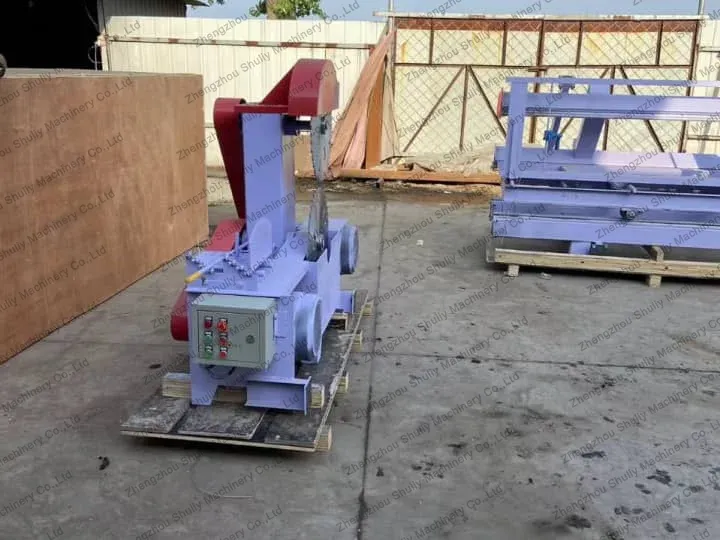

Aserradero vertical SL-50:

La potencia es de 11kw+11kw, soportando corte de troncos de 0-50cm de diámetro, adecuado para las operaciones diarias de corte de madera de tamaño mediano de los clientes. Este modelo es operado manualmente, adecuado para que los clientes ajusten de manera flexible el modo de operación.

Razones para la decisión de compra del cliente

El cliente está muy satisfecho con el diseño estructural y la correspondencia de nuestra máquina de pelado de corteza de madera y el aserradero después de obtener una comprensión profunda del rendimiento de la máquina, el video real, los parámetros técnicos y nuestro servicio postventa.

En particular, la máquina puede procesar con precisión según el tamaño real de la madera del cliente, lo que está totalmente en línea con el estándar de operación de su fábrica. Al mismo tiempo, el cliente también reconoce las respuestas técnicas profesionales de preventa y las soluciones completas de embalaje y transporte que ofrecemos.

Envío y expectativas

Después de confirmar el pedido, Shuliy organizó rápidamente el trabajo de embalaje y envío, y el equipo fue empaquetado profesionalmente para garantizar un transporte seguro.

Este cliente está lleno de expectativas sobre la estabilidad y el funcionamiento de la máquina, y planea actualizar gradualmente otro equipo de procesamiento de madera después de que la máquina entre en funcionamiento para aumentar aún más la capacidad de producción.