SL-50 sliding table sawing machine sold to Guinea-Bissau

Our client is a growing wood processing plant located in Guinea-Bissau, West Africa. They approached us with several challenging production issues:

- Outdated processing methods: Traditional manual or semi-automatic processing methods are slow, labor-intensive, and pose high safety risks.

- Lack of power: Existing sawmill equipment lacks sufficient power when processing locally common high-density hardwoods, resulting in frequent jams that severely impact cutting quality and speed.

- Expansion constraints: Business growth requires processing longer (up to 3 meters) and thicker logs, but existing equipment is unable to handle these demands, directly limiting the factory’s order-taking capacity.

Solution: a customized sliding table sawing machine (Model SL-50)

Based on the customer’s specific needs, we have developed a customized solution that addresses the core issues.

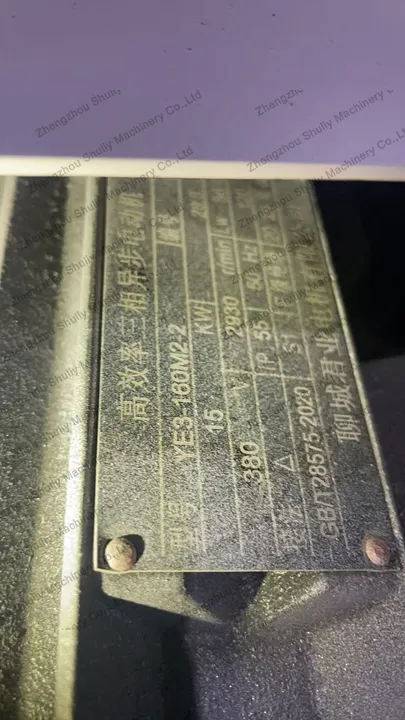

- 15+15kw electric motor

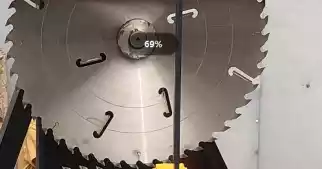

- 3-meter automatic sliding table and 50cm processing diameter

- Cusotmized 380V/50Hz/3-phase standards

| Machine pic | Paramters | Qty |

| Model: SL-50 Power: 15 kW + 15 kW Suitable for log diameters: 0-50 cm Suitable for log lengths: 0-3 m Automatic type | 1 set |

| / | 10 pcs |

Professional packaging to ensure safe transport

We customized an export-standard, reinforced wooden crate for this heavy-duty equipment, featuring rigorous moisture-proof and impact-resistant fixtures inside, ensuring the machine remains intact after weeks of sea transit.

Take action now!

If your factory is also experiencing efficiency bottlenecks and is looking for a powerful sawmill machine capable of handling large, hard logs, please contact us immediately. Our technical experts will listen to your needs and provide you with the most suitable customized solution.