Pressed Wood Block Making Machine

| Brand | Shuliy |

| Final products | Wooden pallet blocks with holes or without holes |

| Size | 75*75mm, 90*90mm, 100*100mm, 145*145mm, 145*100mm, etc. |

| Raw materials | Wood chips, wood shavings, sawdust, etc. |

| Capacity | 3.5-9m³/24h |

You can now ask our project managers for technical details

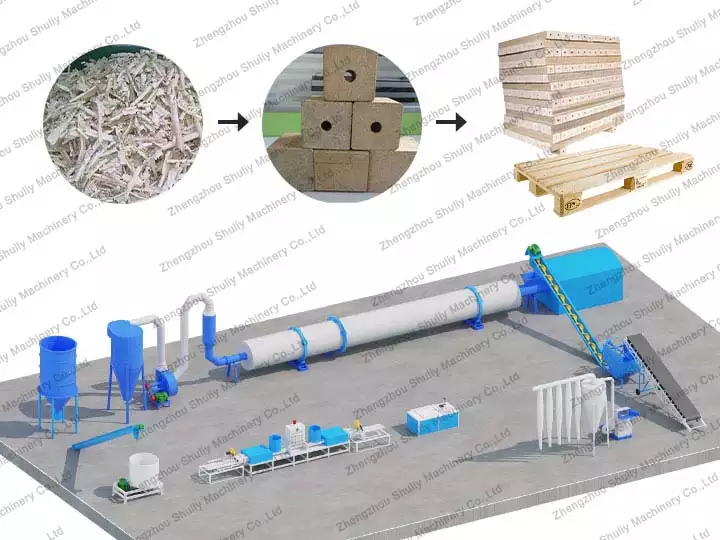

Shuliy wood block making machine is to produce wooden pallet blocks from sawdust, wood chips, wood shavings, coconut shells, etc. by high temperature and pressure. The moisture of raw materials should be <10% and the size should be around 1cm.

This compressed wood pallet block machine has a wide range of capacities due to different outlet quantities. It’s available in double outlets, triple outlets, four-head outlets, etc. The capacity ranges from 3.5-9m3/24h.

According to the hopper shape, we have two models of wood block hot pressing machines. One is the machine with square hoppers and another is the machine with round hoppers.

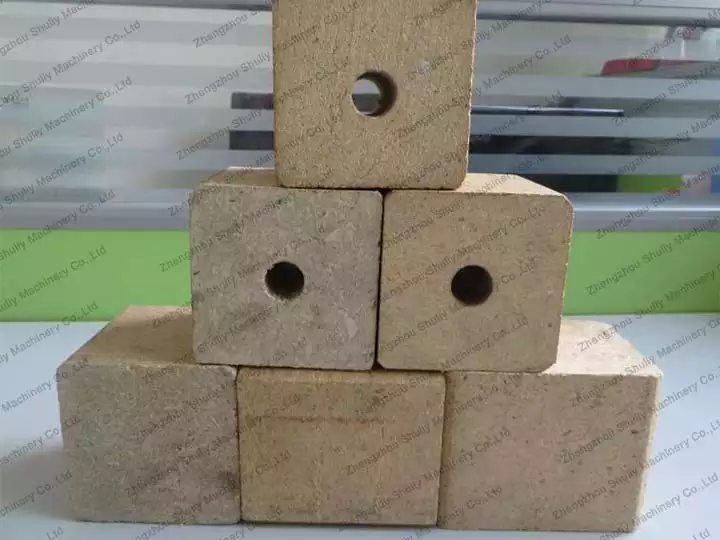

But the final products both are wooden pallet blocks. The wooden pallet blocks have two shapes: with holes or without holes. Also, from the height, the wood blocks can be divided into common standard(2-3mm) and Euro standard(>3mm).

Raw materials for compressed wood blocks

What can be used as raw material if you want to do wood pallet block production?

The following can be used as raw materials:

Wood waste, wood chips, wood shavings, fiber, bamboo, coconut shells, furniture manufacturing waste, construction wood waste, waste paper, bamboo shavings, bark, twigs, leaves, etc.

Final products’ shapes and sizes

After knowing the raw materials, now let’s together see the final product shapes and sizes manufactured by Shuliy wood block making machine.

- Different wooden pallet block shapes: the final products have solid and holed two types.

- Solid: prevent moisture.

- Holed: the heat disappears quickly and the moisture also evaporates quickly.

- Two wood pallet block standards: conventional(2-3mm) and European standard(>3mm).

- Common sizes: 75*75mm, 90*90mm, 100*100mm, 145*145mm, 145*100mm, etc.

For the common size, you should know:

- The size is <100mm, it’s conventional.

- The size is >100mm, it’s the European standard.

Advantages of compressed wood block making machine

- Efficient production. This sawdust pallet block making machine has a capacity ranging from 3.5-9m3/24h, which is efficient.

- Easy operation. Simple and intelligent operation interface, just press the relevant operation button to operate the machine. Even first-time users can quickly grasp the operating essentials.

- Wide application. Various sizes and materials of wood can be used as raw materials to make wooden pallet blocks. Waste wood, wood chips, sawdust, wood shavings and so on are suitable.

- Customization. We can customize the machine according to the wood blocks you want to produce, including but not limited to, outlet quantities, hopper shape, voltage, etc.

Technical parameters of commercial wood block making machine

| Model | Size(mm) | Power(kW) | Capacity(m3/24h) | Density(kg/m3) | Dimension(mm) | Weight(kg) |

| SL-75 | 75*75 | 15 | 3.5 | 550-600 | 4500*750*1200 | 1300 |

| SL-90 | 90*90 | 15 | 4 | 550-600 | 4800*900*1200 | 1500 |

| SL-100 | 100*100 | 16 | 6 | 550-600 | 5000*1000*1200 | 1800 |

| SL-120 | 120*120 | 18 | 9 | 550-600 | 5500*1200*1200 | 2000 |

When choosing a wood chips block making machine, you can use the finished product as a reference. We can recommend the right equipment for you according to your wood block size.

For example, a 3-head wood block machine can only make wooden blocks under 100mm with an output of 6-7m3/24h.

Thus, if you’re interested, get in touch with us now!

Types of wood pallet block making machines for sale

Based on the hopper shapes, we have 2 models available. Now let’s take a look at each of them.

Model 1: wood block making machine with the square hopper

From the appearance, this machine has square hoppers. The screw is in the bottom of the hopper.

Put the raw materials in the hopper and press them into wood blocks.

Model 2: sawdust block machine with the round hopper

The biggest difference is that this model has a motor above the hopper of the machine.

Because of connecting with the motor, there is a mixing function, helping raw materials even before molding.

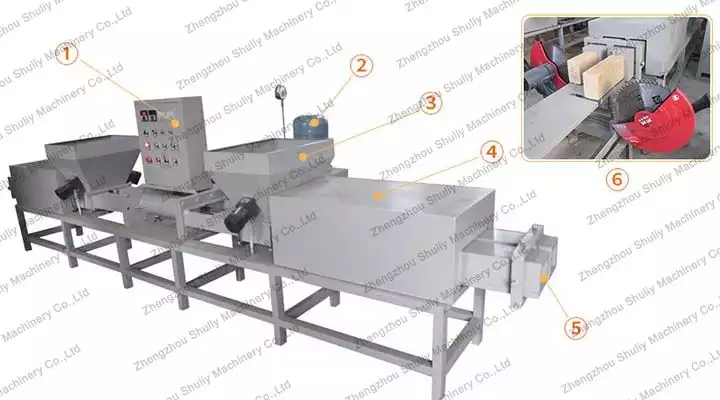

Structure of the wood pallet block making machine

| S/N | Machine part name | Function |

| 1 | Control cabinet | Set all the parameters, which is convenient and fast. Also, it’s safe when using the machine. |

| 2 | Motor | Provide power when the machine works. |

| 3 | Hopper | As the container to hold the raw materials for making blocks. |

| 4 | Working chamber | Core part to produce the suitable wood blocks. It has a high-temperature sheet inside. |

| 5 | Outlet | Finished products come out from this outlet. |

| 6 | Cutting machine | Because the block is whole, you should use the machine to cut the block into a satisfying size. For this machine, Shuliy has the hand sawmill and automatic cutter machine available. You can choose based on your needs. |

How to process the sawdust block?

Actually, it’s very easy to understand how the wood block making machine works.

- Firstly, put the raw materials into the bin.

- Then, stir the raw materials and the materials will enter into the working part.

- Next, the materials go through conditions that are high temperature and high pressure, so form the materials into a shape.

- Finally, the whole wood block is shaped, and you can use the small cutting machine to cut the blocks into the proper ones.

Successful cases of compressed wood pallet block machine

Wood chip block making machine sold to Indonesia

Recently, we exported the sawdust wood block hot pressing machine to Indonesia. Through the conversation, we learned that this Indonesian customer has a wood processing plant and needs to process the leftover scrap after wood processing and sell it by himself.

Therefore, our sales manager recommended our wood block making machine to him. Attracted by the efficient production, customization and simple operation of our machine, the customer immediately placed an order.

After the machine was produced, we delivered the machine to his destination by sea.

Get in touch with us for waste wood recycling solution!

Are you looking for an efficient solution to make profits from wood waste? If yes, contact us now!

As a professional wood machine manufacturer and supplier, we have different wood recycling equipment to help you make profits, such as compressed wood pallet machine and wooden pallet block making machine.

We’ll provide the most suitable solution according to your demands. So, don’t hesitate and contact us immediately!