Wood Sawmill Machine for Wood Cutting

Lumber Mill | Bandsaw Mill

Types: vertical bandsaw, log sliding table saw, portable sawmill

Processed wood dia.: 0-500cm

Matched equipment: carriage, grinder

Applications: ancient building construction, wooden boat manufacturing, furniture manufacturing, etc.

Countries sold: the USA, Yemen, Morocco, Papua New Guinea, etc.

Warranty period: 1 year

The wood sawmill machine is to cut wood logs at the required thickness for further processing, such as making furniture, or for sale. It can handle wood logs within 0-500cm.

We have three types of sawmills for sale: log sliding table saw, vertical bandsaw and portable sawmill. All can be used for log cutting and are suitable for small, medium and large-scale wood processing plants.

Introduction video of wood sawmill machine

Through watching the following video, you can have an initial overview of our three sawmills.

What materials are suitable for the wood sawmill machine?

Before you get to know the three models of sawmills in detail, it’s important to know which woods can be treated and what they are used for afterward.

The lumber mill can handle many types of wood, including but not limited to:

- Logs: such as pine, oak, birch, square, timbers, etc.

- Scrap wood: e.g. scrap furniture, construction waste, etc.

- Branch wood: e.g. sections, branches, tree trunks, etc.

The wood boards handled by the log sawmill are used for a wide range of purposes, mainly including:

- Building materials: used for house construction, bridges, wooden structure buildings, etc.

- Furniture manufacturing: for making various kinds of furniture, such as tables, chairs, cabinets, etc.

- Flooring and decoration: used for floor laying, wall decoration, ceiling, etc.

- Packaging materials: used for making wooden boxes, pallets and other packaging products.

- Crafts: for making all kinds of wooden crafts, artworks, etc.

- Wooden boat manufacturing: used to make various types of wooden boats, such as fishing boats and rowing boats.

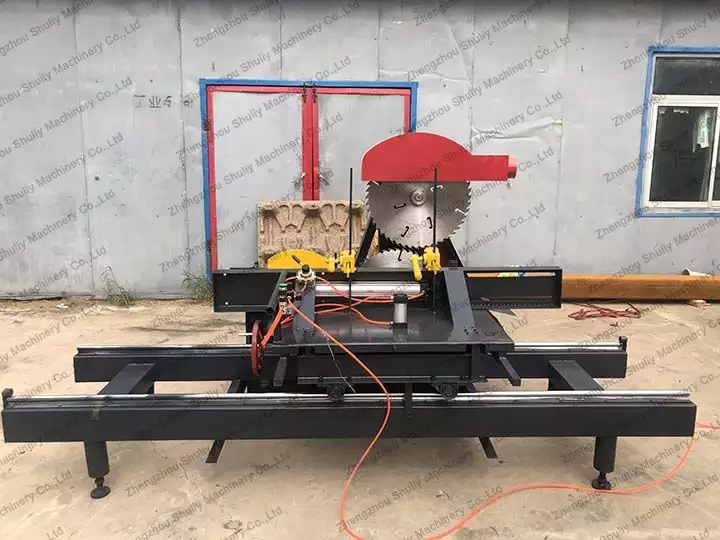

Type 1: Small log sliding table saw for sale

This sliding table sawing machine has the manual type and automatic type, suitable for small wood processing plants. Its common spots are summarized as follows:

- Suitable wood dia. and length: small diameter, short wood, the maximum diameter is ≤ 50cm. The common length is 4m, and it can be increased.

- Adjustable cutting thickness: control the distance of the track and stopper of the wood sawmill machine to fit your needs.

- Equipped with mobile wheels: easy to move and work outdoors when using this circular table push log saw.

- Quality saw blade: made of alloy, long service life(generally half a year).

Structure of automatic wood sawmill machine

The composition of this round log sliding table sawmill is very simple. It has machine head, track, control cabinet, handwheel, wood fixing device, stopper, motor and saw blade.

The wood fixing device is pneumatic and this mini circular saw machine has two motors to control blades.

Advantages of the bandsaw mill

- Infrared recognition. The use of infrared light can be more precise and accurate for cutting wood boards.

- The saw blade can be sharpened with a grinder. Because of a long time of use, the saw blade will become dull. This time you can use the grinding machine for sharpening so that the saw blade is sharp and shiny again.

- The device to fix the wood. This device can be set to manual or steam. This can be chosen according to your needs.

- When this log sliding table saw is working, the working track is cut→reset→cut again. In the process of resetting, the machine does not carry out the sawing work.

Technical parameters of the wood sawmill machine

According to the wood log lengths, we divide this wood cutting machine into three models: SL-300, SL-400 and SL-500. The detailed specifications of these three models are shown below for your reference.

| Model | SL-300 | SL-400 | SL-500 |

| Max sawing wood length | 4000mm | 4000mm | 4000mm |

| Max sawing wood diameter | 3000mm | 4000mm | 5000mm |

| Motor power | 7.5kW*2 | 11+7.5kW | 11kW*2 |

| Dimension | 8000X1600X1600mm | 8000X1600X1600mm | 8000X1600X1600mm |

| Weight | 750kg | 750kg | 750kg |

For the SL-500 model, we have the specific parameters, shown below:

| SL-500 model | 1m | 1.5m | 2m | 2.5m | 3m | 4m |

| Feed length | 0-100cm | 0-150cm | 0-200cm | 0-250cm | 0-300cm | 0-400cm |

| Feeding diameter | 0-500mm | 0-500mm | 0-500mm | 0-500mm | 0-500mm | 0-500mm |

| Motor Power | 11kW*2 | 11kW*2 | 11kW*2 | 11kW*2 | 11kW*2 | 11kW*2 |

| Total Weight | 500kg | 550kg | 600kg | 650kg | 700kg | 750kg |

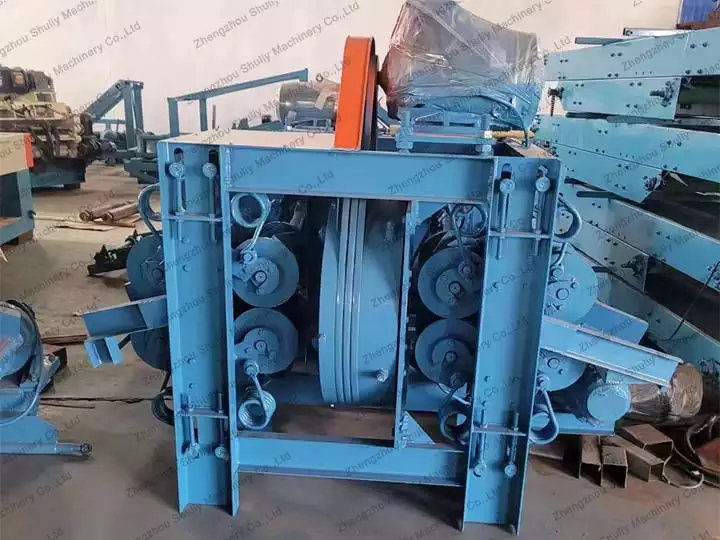

Type 2: Vertical bandsaw machine for sale

This type of wood sawmill machine can handle wood up to 80cm-100cm in diameter and is suitable for medium and large sawmills.

If using this bandsaw mill, you need to lay the foundation in order to smoothly use it.

Compared to these three types of sawmills, this vertical bandsaw log mill is the most cost-effective and popular in the market. If you need or have any questions, please feel free to contact us.

Composition of the commercial wood sawmill machine

This bandsaw mill is mainly composed of main machine and carriage.

Details are bed, wheel, upper wheel lifting and tilting device, band saw blade tensioning device, saw blade guiding device, working table, guiding plate, and so on.

When working, the bandsaw blade is connected to the two saw wheels for a one-way linear motion to cut wood. Also, some parts are underground.

Characteristics of quality sawmill machine

- Saw blades can also be sharpened. That is, when the saw blade is dull, the saw blade can be sharpened by using the grinder machine.

- This machine has high efficiency and the best cost performance.

- The thickness of the cutting plates is not adjustable.

- One thing to note is that when working on the foundation, part of the machine is underground.

Failure analysis of common problems

When the saw blade is running with the saw wheel, it moves back and forth or suddenly goes in and out, this situation is called dropping the blade. There are several reasons as follows:

- Maybe the upper wheel is tilted, adjust the upper wheel.

- The outer diameter taper of the saw wheel is too large, and the saw wheel is not flat. Fine grinding, leveling the rim surface.

- The wood is split and jammed when returning to the material, pulling it off. Pay attention to wood defects when operating.

- The clip saw is hot, and the suitability of tension is reduced or even disappeared. Clear the resin sawdust on the saw wheel and saw blade and the debris on the saw card, and brush oil frequently.

Saw out of the wood bending, there are generally the following reasons(bandsaw mill machine reasons):

- The tensioning device does not work, the heavy hammer is too light. General repair tensioning device, weight hammer.

- Saw wheel rim surface wear, front, and rear diameter are not the same as grinding wheel rim surface.

What are the parameters of the modern wood sawmill machine?

| Model | SL-3000 | SL-5000 |

| Saw wheel diameter | 1600mm | 1250mm |

| Max sawing wood diameter | 800mm | 1000mm |

| Motor power | 30KW | 45KW |

| Sawing thickness setting | CNC | CNC |

| Wood clamping model | Electric | Hydraulic |

| Max sawing wood length | 4000mm | 6000mm |

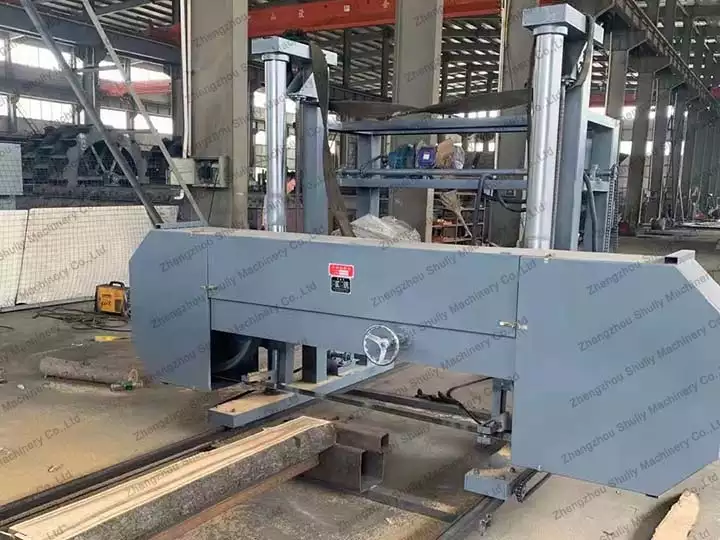

Type 3: Portable wood sawmill machine

The big timber sawmill, also known as a gantry saw, is named after its shape. This portable band saw mill can handle wood up to 150cm-250cm in diameter, ideal for large factories, selling or exporting lumber.

This large bandsaw mill is easy to use and saves labor. And the cut surface for discharge is flat. The track can be as long or as short as you want. If you have any needs, please feel free to contact us!

What makes up the biggest wood sawmill machine?

This portable saw milling machine is mainly composed of two saw wheels on the left and right, sawing machine, the working table, the control cabinet, etc.

When working, the track of the horizontal sawmill is fixed and the saw blade section is in motion. The wood is stationary on the track and the saw blade area is working in motion.

Features of the wood sawmill machine for sale

- There are two types of control available: CNC and PLC.

- When working, the track is fixed and the saw blade moves.

- The diameter of the dealt wood is large, suitable for large sawmill(wood mill near me or other areas) use.

- The thickness of the wood to be cut is adjustable.

- The machine is determined according to the maximum diameter of the wood-handled.

Sawmill wood cutting machine specifications

| Model | SL-1500 | SL-2500 |

| Saw wheel diameter | 1000mm | 1070mm |

| Max sawing wood diameter | 1500mm | 2500mm |

| Motor power | 37KW | 55KW |

| Sawing thickness setting | 350mm | 450mm |

| Max sawing wood length | 6000mm | 6000mm |

| Weight | 4500kg | 5500kg |

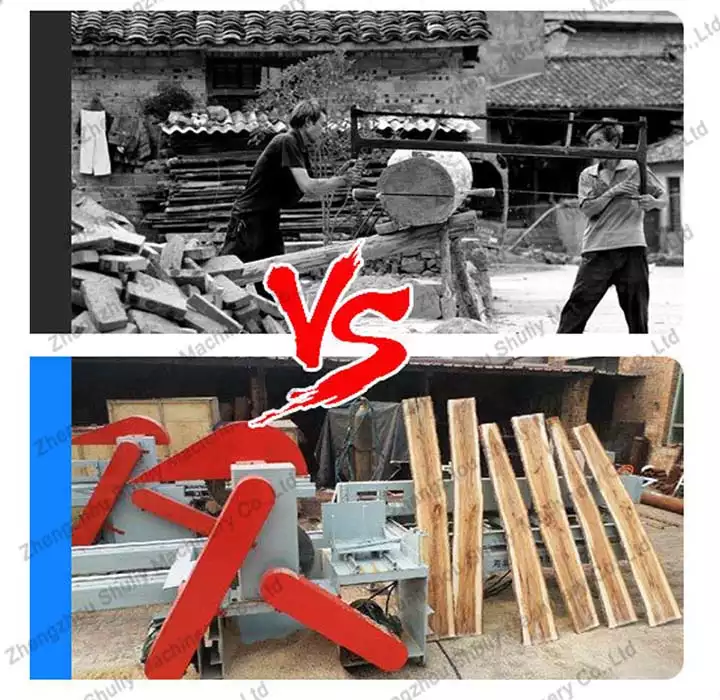

Why use the automatic wood sawmill machine?

It is well known that tree resources are found all over the world and have a wide range of uses. There are also many uses of trees. For example, making furniture, exporting lumber, etc.

But when you want to do tree business, you need to do some processing of the raw material. At that time, one bandsaw mill can make more profits for you.

Besides, there are always selling logs to sawmills. That’s why there is the wood saw machine, which has to be used to process the trees in a certain way.

Of course, the use of the final product is different and requires different machines, which requires a flexible choice according to your needs.

Matters needing attention

- Fixed with a dedicated operator of the machine working area, the operator should carefully read the handover records and know the last shift of its operating conditions and the existence of questions.

- Check the safety equipment, it should be completely free of defects. Do not operate machine tools without protective equipment.

- Cutters and wood should be correctly clamped, fastened, and reliable.

- Pay close attention to the operating conditions, smooth condition, temperature rise condition sound condition of the wood cutting machine. If any abnormalities, you should immediately stop to solve the problem before continuing to work.

Get a quote now!

Want to perform wood log cutting quickly and efficiently? Our sawmill can help you.

In addition to this, we also have wood log debarker to help you carry out tree processing more efficiently. Contact us to start your tree treatment journey!