Commercial Wood Shaving Machine for Animal Bedding

Wood Shavings Machine | Shavings Mill

Machine brand: Shuliy

Capacity: 200-3000kg/h

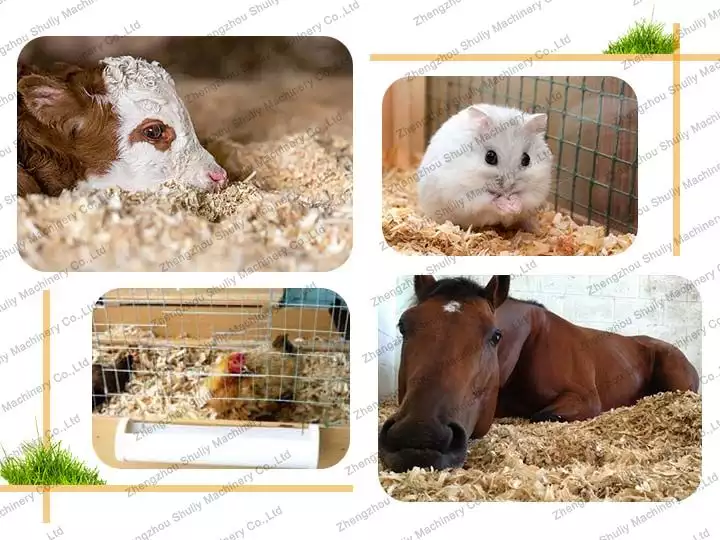

Applications: animal bedding (horse bedding, chicken bedding), filler during transportation, paper mills, etc.

Final products: uniform wood shavings, adjustable thickness of wood shavings

Advantages: cost-effective machine price, after-sales service, 1-year warranty period

Wood shaving machine is mainly used for mass production of thin shavings of uniform thickness by processing logs, branches (twigs), etc. Wood shavings can be used as horse bedding, chicken bedding, etc.

It can process wood with a capacity of 200-3000kg/h. And our wood shavings machine can use electric motor, diesel engine or diesel engine unit, which is flexible for you to choose from.

Because of the wide range of machine options available, our machines are very popular overseas, such as South Africa, Jamaica, the USA, UAE, Mauritius, etc.

It should be noted that when shaving logs, it is better to use the wood debarking machine first and then shave.

Hot sale wood shaving machine from Shuliy

As mentioned above, we have a variety of wood log shaving machines.

- By power type: electric motor, diesel engine and diesel engined unit.

- By machine size: small and large wood shavings mill.

- By customization: big tyres, frame, vertical feeding port, incline feeding port, etc.

We design these models to cater to the market needs and customers’ demands. So, if you are interested, or you have any unique ideas, welcome to contact us!

Attractive features of wood shavings machine for animal bedding

- Capacity of 200-3000kg/h: using the wood shaving machine can produce 200-3000kg of wood shavings per hour, which is highly efficient.

- Adjustable thickness of the wood shavings: by adjusting the blade inclination, the finished product thickness can be controlled.

- Simple structure: the internal structure is composed of a blade and a single disc, which is very simple.

- Customization: voltage, feeding port, tyre, frame, etc.

- Advantageous price: with the integration of industry and trade and the updated technology, we can produce multiple machines in one batch, which reduces the cost, so our machines are competitively priced.

Applications of wood shavings

After producing wood shavings, what are wood shavings used for?

- Industrial uses: particle board(plywood) making, raw materials for wood pulp paper in the paper mills, transport filler for fragile goods in the transport companies, bioenergy, etc.

- Making nests: animal bedding for chickens, horses, pigs, cattle, sheep, etc.

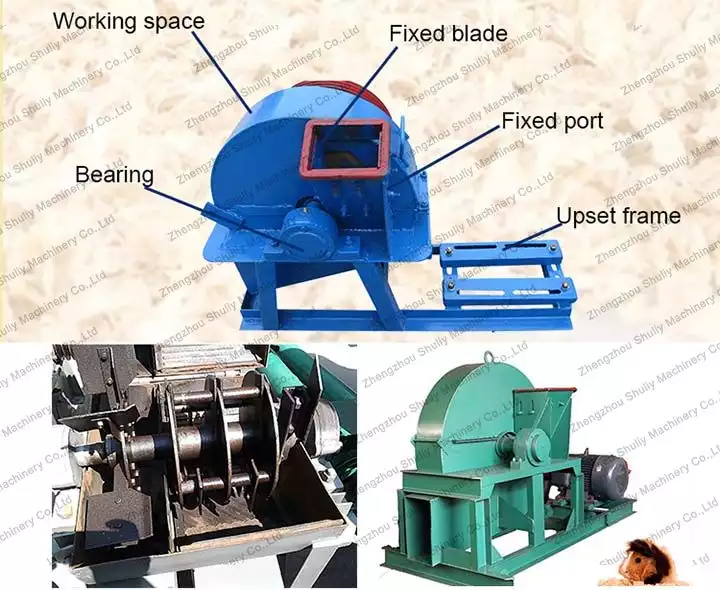

Composition of commercial wood shaving machine

It includes the frame, the internal structure of the blade, and the knife plate.

The wood enters the shavings mill machine by the inlet, and the shavings are sliced by the blade inside the machine. The size and thickness of the shavings come out evenly, and there is no difference with the shavings from the wood factory by hand.

Working principle of wood shavings mill for sale

This machine is automatically crushing and processing wood into shavings.

After the raw material enters the feeding port, it will first enter the crushing chamber by the blade.

Under the action of high-speed rotating blades, shavings are made. Then the wind generated by the built-in wind blade is pumped to the material outlet through the outlet or external fan.

The size of the shavings can be adjusted to suit various needs by the blade inclination.

Successful cases of wood shavings machine

Small wood shaving machine sold to South Africa

This year, a customer from South Africa wanted a wood shaving machine for animal bedding. So our sales manager recommended this machine to him.

He was attracted by our machine’s price and performance. Thus he placed an order immediately.

After that, we manufactured the machine and arranged shipping to his destination. After he received it, he was very satisfied and said he would cooperate with us again when he had the chance.

Wood shavings machine for horse bedding exported to UAE

A lumber harvester company in UAE wants wood shavings as horse bedding, our wood shaver machine was designed specifically for this purpose and produces high-quality wood shavings.

Therefore, he bought the machine. After using a while, he said, “This pine shaving machine can efficiently process wood into fine and comfortable horse bedding, which is favored by the local market. I love it very much!”

Technical parameters of industrial wood shaving machine

| Model | Capacity | Power | Feeding inlet size | Blade | Machine size |

| SL-420 | 200-300kg/h | 11kW | 150*120mm | 4pcs | 1200*600*700mm |

| SL-600 | 300-500kg/h | 15kW | 200*180mm | 4pcs | 1500*1000*900mm |

| SL-800 | 600-1000kg/h | 30kW | 250*260mm | 8pcs | 1750*800*1200mm |

| SL-1200 | 1500-2000kg/h | 55kW | 420*400mm | 8pcs | 2000*1100*1300mm |

| SL-1500 | 2000-3000kg/h | 75kW | 460*490mm | 12pcs | 2200*1200*1500mm |

We have many types of equipment for you to choose from, with output ranging from 200-3000kg per hour. How to choose the right one? Please continue reading.

Tips on choosing a suitable wood shavings machine

- Determine the needs. Firstly clarify your use, such as for animal bedding, garden mulching, packaging filling, etc.

- Consider capacity. Choose the right capacity suitable for your production needs.

- Check quality. Pay attention to the materials and processes used in the manufacturing of the planer to ensure excellent quality.

- Evaluate energy consumption. Select an energy-saving machine with low energy consumption to reduce production costs and meet environmental requirements.

- Easy operation. You can use the machine without much training, reducing the difficulty of operation.

- After-sales service. Understand the after-sales service provided by the manufacturer, including equipment installation, commissioning, training and maintenance. Choose a manufacturer with perfect after-sales service to ensure that problems during the use of the equipment can be solved in a timely manner.

- Manufacturer reputation. Refer to the evaluation and feedback of other users and choose brands and manufacturers with good reputations and high credibility.

- Reasonable price. Comprehensively consider the performance and price of the machine, choose cost-effective equipment, and avoid sacrificing quality due to low price.

Contact us for wood shaving machine price!

Know how to produce high-quality wood shavings for animal bedding? Contact us and we will recommend the most suitable and cost-effective wood shavings mill for you!