Wood Crusher Machine for Sawdust Making

Wood Shredder | Sawdust Making Machine

Machine brand: Shuliy

Capacity: 300-4000kg/h

Power: electric motor or diesel engine

Machine appearance: various types, and we can also customize the machine to fit your needs

Features: simple structure, easy operation, long service life

Service: after-sales service, operation manual, customization, etc

Warranty period: 12 months

The wood crusher machine is to shred wood, branches, twigs, fir, etc. into sawdust with 3-14mm for charcoal or paper making, with a capacity of 300-4000kg/h. Generally, the raw material has a size of 10-30cm.

Featuring low investment, high productivity and good economic benefits, our sawdust making machine is popular in the world, such as Turkey, Indonesia, Czech, the UK, etc.

Features of wood sawdust making machine

- Capacity of 300-4000kg/h. Our wood shredder can make 300-4000 kg of sawdust per hour by wood pulverizing, which is efficient.

- Processing hardwood, softwood, furniture waste and forest waste. The wood crusher has a wide range of applications for waste wood materials, such as wood logs, construction templates, wood furniture, tree branches, etc.

- Simple structure and easy operation. It consists of motor, internal structure(blade, blade plate, hammer and screen) and frame, easy to understand. Only one person is needed to operate the machine.

- Quantity screen and hammers. They’re made of carbon steel, which has a lifetime of 3-5 years.

- Competitive price. We produce and sell our own products, ensuring quality while having the most competitive prices in the market during the same period.

- Three types of power systems. Electric motor, diesel engine and diesel-engined unit for wood crushing machine use.

- Various machine appearances. Machine with enlarged incline feeding port, machine with big tyres, machine outlet with conveyor, machine with cyclone, etc.

Commercial wood crusher machine for sale

As a professional wood crusher manufacturer and supplier, our wood machines cover all types of machines in the market. Details are as follows.

Small wood crusher machine

From machine type: equipped with cyclone, incline discharging port, tyres, pushing frame, etc.

Sawdust making machine with different power devices

This kind of wood shredding machine can use electric motor, diesel engine or diesel-engined unit as power to drive its working.

Mobile timber crusher machine

This type is equipped with tires, which allow the equipment to move flexibly around the workplace to meet different needs.

What are the parameters of the log pulverizer?

| Model | Capacity | Power | Feeding size | Outlet size |

| SL-420 | 300-400kg/h | 11kW motor or 15hp diesel engine | 10cm | 0.3-0.8cm |

| SL-500 | 500-600kg/h | 18.5 kW motor or 30hp diesel engine | 15cm | 0.3-0.8cm |

| SL-600 | 800-1000kg/h | 30 kW motor or 60hp diesel engine | 17cm | 0.3-0.8cm |

| SL-700 | 1200-1500kg/h | 37 kW motor or 60hp diesel engine | 20cm | 0.3-0.8cm |

| SL-900 | 2000-2500kg/h | 55 kW motor or 80hp diesel engine | 22cm | 0.3-0.8cm |

| SL-1000 | 3000-3500kg/h | 75kW motor or 110hp diesel engine | 26cm | 0.3-0.8cm |

| SL-1200 | 3500-4000kg/h | 90 kW or 130hp diesel engine | 28-30cm | 0.3-0.8cm |

According to the above table, you can see that our wood pulverizer can crush different wood raw materials in large quantities.

You can choose the right machine according to the size of the wood raw materials you want to shred and the output.

Raw materials processed and applications of small wood crusher machine

Since it was mentioned above to select equipment based on the wood size, let’s now look at what raw materials can be pulverized and what the applications are.

The raw materials that can be processed by this wood shredder include:

Wood cubes, construction templates, wood trimmings, logs, branches, straws, segments, twigs, branches, trunks, leaves, bark, pine, birch, oak, walnut, poplar, willow, paulownia, etc.

After producing sawdust, it can be used for:

- Making charcoal

- Making paper, edible fungus, particle board, sawdust board, high-density board, medium fiber board, etc.

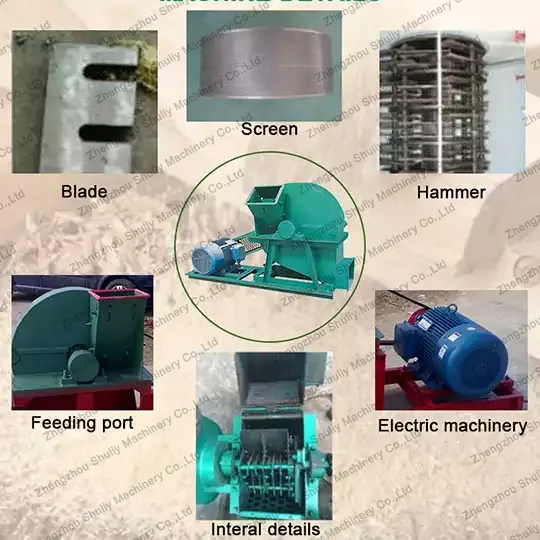

Structure of the wood crusher

In general, the structure of this wood log pulverizer is very easy to understand. The wood crusher machine design is always catering to your needs. It can be roughly summarized in the following parts.

- Power system: our wood crushing machine can choose the motor or diesel engine, according to your needs.

- Internal structure: knife plate, blades, hammer blades, screen(determines the fineness of the finished sawdust).

Spare parts of the wood shredder machine

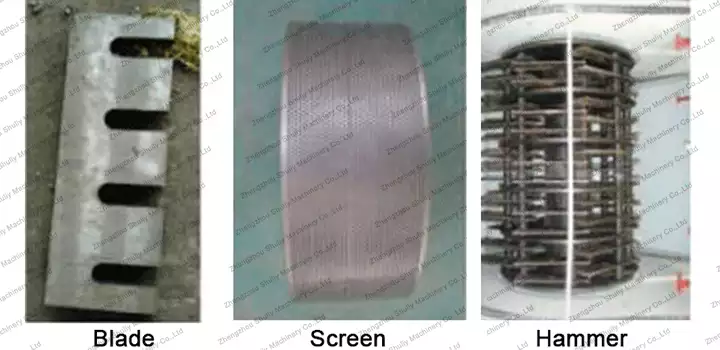

The spare parts of Shuliy wood crusher have blades, hammers and sieves.

- The blade in the wood crusher machine is to shred wood material, the primary treatment compared to the hammer.

- The hammer in the multifunctional crusher is used to crush wood into sawdust. It hammers constantly until the sawdust can meet your requirements.

- Texture: carbon steel

- Installation: easy to change

- Lifetime: 1-2 years

- The screen in the multifunctional crusher is used to unify the size of sawdust for further reprocessing.

- Texture: carbon steel

- Size: adjustable, 0.3-1.2mm

- Installation: easy to change

- Lifetime: 1-2 years

- After-sales service: video and user manual support

How does this wood crusher machine work?

After understanding this machine structure, let’s see how this shredder crushes wood into sawdust. The working process is:

- Feeding. Logs or wood waste enter the shredder through the inlet, feeding can be done manually.

- Crushing & hammering.

- After entering the wood crusher, the blades will crush wood waste into smaller pieces or strips.

- Then through the impact of the high-speed rotating hammers or blades, the wood is further crushed into smaller particles or powder.

- Screening. Next, screen crushed wood by the screen aperture. Wood particles that meet the standards will proceed to the next process, and particles that do not meet the required size will be returned to the crushing area for further crushing.

- Discharging. Finally, qualified wood sawdust is discharged through the discharge port.

Precautions for using the sawdust making machine

- When working, if the machine is partly underground, you should choose a good location to place the machine firstly.

- The smallest model of wood crusher should be equipped with the cyclone. Because the cyclone has a dust collection function, it can avoid dust sawdust flying around during use.

How about the wood crusher machine price?

When shopping for a machine, you will definitely focus on the machine price, list some factors that affect the sawdust making machine price(also applicable to the hammer mill wood crusher) for your reference.

- Configuration. As a sawdust making machine manufacturer, we know that different configurations have different prices. It’s very common to know that the price is higher along with the better configuration.

- International exchange rates. Because the current international situation is constantly changing, the exchange rate is also in constant fluctuation. Naturally, the price of machines will be affected by this influence.

- Machine material. It’s very easy to understand. For example, a machine manufactured with normal metal material is cheaper than a machine produced with stainless steel material.

Maintenance of wood shredder

- The bearing should be filled with lubricant promptly. The bearing should be filled with lubricant once in 3-4 hours for continuous operation.

- After using the triangle belt for some time, the tightness should be adjusted again and it is advisable to decrease by 6-10mm.

- Clean the machine every day after work, check whether there are cracks or other problems, and repair the machine in time.

Global cases of Shuliy sawdust crusher machine

SL-420 wood waste crusher to Czech

Our wood waste crusher was successfully exported to the Czech Republic, where it is highly effective in processing hardwood and softwood waste in the context of the abundant forest resources there.

Our wood waste crushing machine helps Czech customers realize the recycling of wood waste into biomass fuels and organic mulch and other high-value products.

Diesel-powered timber crusher machine for Indonesia

In Indonesia, the timber crusher machine we supplied plays a key role in dealing with the large amount of biomass waste generated by the palm oil industry.

By quickly crushing the waste tree trunks and branches into granular materials suitable for bioelectricity generation, it effectively promotes the development of local sustainable energy and reduces environmental pollution.

Mini tree branch crusher to Turkey

A large Turkish recycling company has introduced our tree branch crusher, which is specially designed to process large quantities of waste wood from furniture factories and construction sites.

The machine is highly adaptable and has excellent crushing effect, providing strong support for the local environmental protection and energy regeneration fields.

Inquiry about timber crusher machine price!

Want to know how to recycle scrap wood into wood chips or sawdust? Contact us and we’ll provide you with the best solution and offer!