Shuliy wood debarking machine assists Sierra Leone carpentry shop

Very happy to have worked with a customer in Sierra Leone on a wood debarking machine. This customer is located in Sierra Leone and runs a carpentry shop specializing in the production of high-quality house posts. He uses local high-quality timber as raw material, but faced problems with debarking logs and processing wood, and needed to find an efficient solution to improve productivity and wood utilization.

What are his needs?

His main need was to increase the efficiency of wood processing, especially in the debarking process, in order to minimize waste and reduce production costs. He also wanted to maintain the quality of the timber to ensure that the final house posts produced would be strong and long-lasting.

Shuliy solution for Sierra Leone

We supplied two key machines to this carpentry shop: a wood crusher and a wood debarking machine. These machines were integrated into the customer’s woodworking process to increase efficiency and meet the customer’s needs.

In addition to these, as this customer operates a woodworking shop, we also recommended the relevant wood processing equipment, as shown in the table below:

| Item | Specifications | Qty |

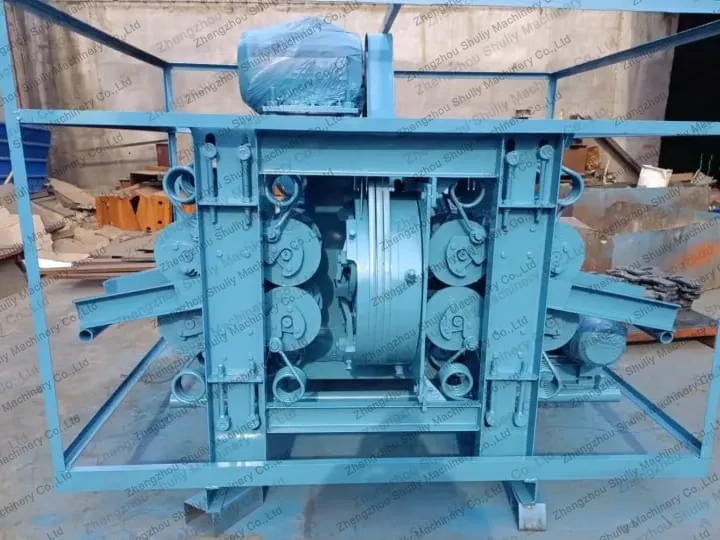

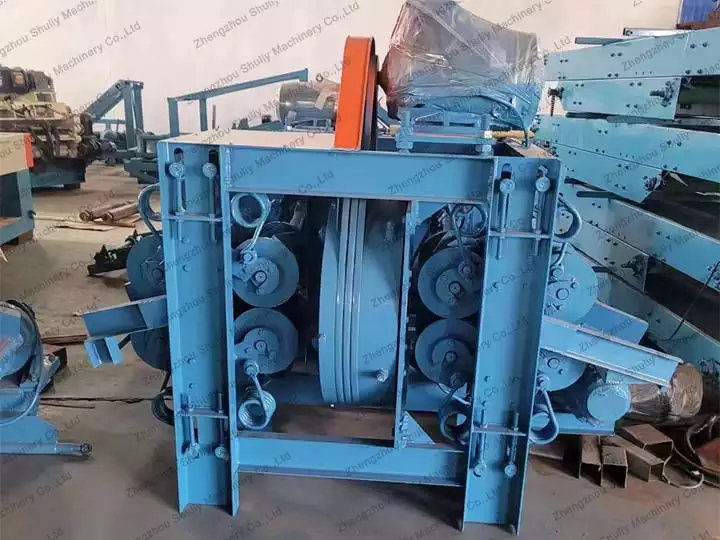

| Wood debarker | Model(SL):420 Max diameter:400mm Knife quantity: 5 Main power: 15 kw+4kw Machine weight: 1.75t Package size: 2500*1400*2000mm | 1 pc |

| Wood crusher | Model: SL-700 Power: 37KW Capacity: 1000-1200KG/H Feeding inlet size: 220*200mm | 1 pc |

CNC woodworking lathe | Model: Single-axis turning, milling and carving integrated CNC woodworking lathe Processing size: length 1500mm*diameter 300mm Motor power: 4KW+3.5KW Alpha pure servo motor Motor speed: 0-6000rpm/min Transmission mode: imported silver guide rail/slider/TBI ball screw Drive: YAKO drive Inverter: Best Inverter/Alpha Servo Variable Frequency Driver Control system: LRSK 1000TC dedicated control panel conversion air-cooled spindle Processing accuracy: ±0.05mm Main functions: Turning, slot milling, drilling, cylinder engraving | 1 pc |

Woodworking engraving machine | Model: 1325 woodworking engraving machine (heavy bed) stroke: 1300*2500*200MM Spindle: Jester 3.2KW water-cooled spindle Control System: Weihong Control System Motor: Skyworth stepper motor Inverter: Best Inverter Driver: 860 drive Working desk: Suction clip dual-purpose table Transfer method: Square rail rack drive, Z axis 2510 lead screw Square rail model: The XYZ three axes are all Taiwan Shangyin 20 square rails Engraving speed: 10-15M/min Idle speed: 25M/min Precision: The diagonal accuracy is around 0.5MM Repeatability: 0.0254MM Operating Voltage: 220V/380V Tool diameter: φ3.175, φ6 , φ12.7 | 1 pc |

In addition to these, related accessories are recommended to him based on our experience, such as blades, screens, hammer for wood shredder, and blades for wood debarking machine. Finally, the customer placed an order for these machines.

Highlights of wood debarking machine for customer

- Efficient debarking: Shuliy’s wood log debarker is known for its superior debarking technology, which removes the outer layer of wood quickly and accurately, resulting in less waste and more efficient wood processing.

- Wood preservation: This woodworking shop takes the quality of its wood very seriously. Our wood peeling machine ensures that the wood remains undamaged during the peeling process through careful operation and tool design, delivering high-quality wood to produce strong and durable house posts.

- Self-operated: Our machines are so easy to operate that he can quickly master their use. This saves time and training costs for carpentry shops and makes operation easier.

- Resource efficiency: The wood debarking machine helps to reduce wood waste, thus increasing resource efficiency. This is especially important for woodworking shops that use local wood resources.

Buy a wood debarking machine now!

If you also want to carry out wood treatment equipment, come and contact us! We will provide you with the optimal solution and quotation!