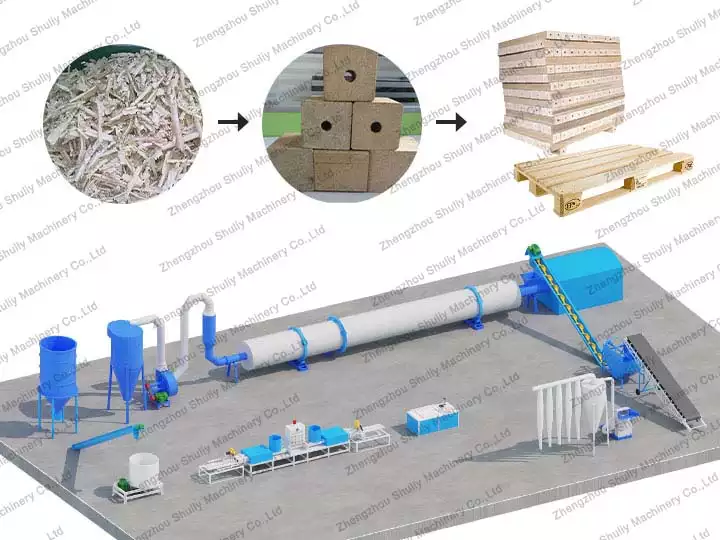

Compressed Wood Pallet Block Production Line

| Brand | Shuliy |

| Final products size | 75*75mm, 80*80mm, 90*90mm, 90*120mm, 100*100mm, 100*115mm, 100*140mm, 140*140mm, also customizable |

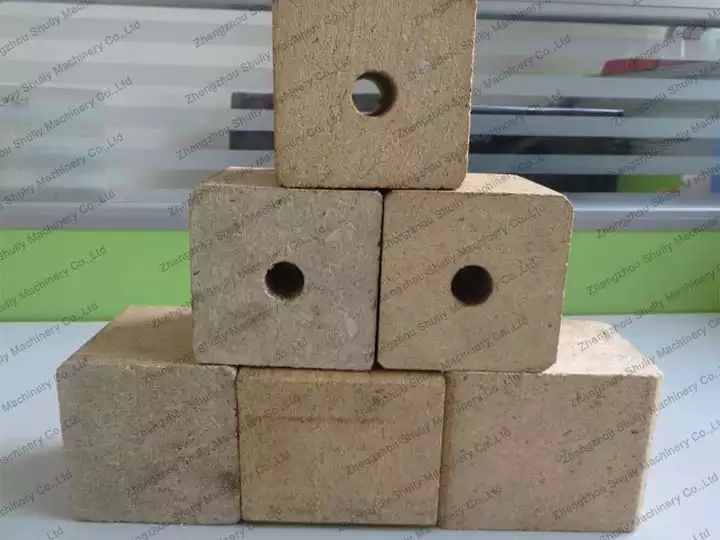

| Wood pallet block types | With a hole or without a hole |

| Sawdust block standards | Common and European standard |

| Applicable raw materials | Sawdust, wood chips, wood shavings, etc. |

| Requirement for raw materials | Moisture is less than 10%. |

You can now ask our project managers for technical details

This wood pallet block production line is processing sawdust, wood shavings, wood chips, etc. into wooden pallet blocks through high temperature and pressure.

There is a requirement for raw materials used for making sawdust blocks. The moisture should be less than 10%.

The final product is the wood block with a hole or without a hole. It has common and European sizes(75*75mm, 80*80mm, 90*90mm, 90*120mm, 100*100mm, 100*115mm, 100*140mm, 140*140mm, also customizable).

The wood blocks are widely used in the fields of wooden pallets, packaging, construction, etc. This line can effectively utilize the waste wood, which is environmentally friendly and economical.

Working video of wooden pallet block production line

By watching this video, you will know that the equipment included in the wood pallet block production line. The equipment shown in the video has glue mixer→wooden block making machine→cutting machine.

Equipment used for compressed wood pallet block production line

There are various combinations of the sawdust block making machine line. The following will take the configuration of producing 90*90mm wood blocks as an example to introduce.

Hammer mill crusher

Because the wood waste size varies, and the size for the wood pallet block production is around 1cm, a hammer mill shredder is required.

| Model | SL-600 |

| Input feeding size | 180*180mm |

| Capacity | 800-1000kg/h |

| Power | 30kw |

Dryer machine

The moisture content of the crushed materials for making wood blocks should be below 10%. The sawdust dryer machine is applied.

| Model | SL-2 |

| Motor | 5.5kw |

| Capacity | 500-600kg/h |

Glue mixer

Before hot pressing wood blocks, it’s necessary to mix the glue and processed wood waste.

In the pressed wooden pallet block production line, it’s important because the wood itself is not sticky, glue needs to be added to go for bonding.

| Brand | Shuliy |

| Motor | 7.5kw |

| Capacity | 1800kg/h |

| Dimension | 1500*1000*130mm |

Wooden pallet block making machine

After glue mixing, you should choose a suitable sawdust block making machine to produce high-quality wood blocks.

| Machine name | Four -head pallet blocks making machine |

| Size | 90*90mm(customizable) |

| Motor | 15-18kw |

| Capacity | 4m³/24h(different for different materials) |

| Density | 550-600kg/m³ |

| Material consumption | 550-600kg/m³(wood shavings, sawdust) |

| Glue consumption | 80-100kg/m³ |

| Temperature control | PID |

| Dimension | 4800*760*1300mm |

| Weight | 1300kg |

Automatic cutting machine

When wooden blocks (with a hole or without a hole) are ready, the cutter machine should be used.

It can cut wood pallet blocks into required lengths, easy to use and sell.

| Model | SL-1800 |

| Power | 5.5kw |

| Dimension | 1600*1200*1300mm |

| Weight | 300kg |

| Saw diameter | 400mm |

| Capacity | 1800pcs/h |

| Cutting length | Adjustable |

Spotlights of the wood sawdust pallet block production line

- High automation. Shuliy wood pallet block production line works with the help of a mechanism, and 2-3 persons are enough to operate the whole line.

- Waste recycling. The raw materials used in this line are waste wood, wood chips, wood shavings, and scrap wood, which are recycled for the production of sawdust blocks.

- Regular and European standard block production. Our line can produce various wood block sizes, such as 80*80mm, 90*90mm, 90*120mm, 100*100mm, 100*115mm, etc. The block that exceeds 100mm is a Euro standard.

- Flexible machine selection.

- According to the size and humidity of raw materials, you can flexibly find the wood crusher and dryer machine.

- According to budget and needs, you flexibly select the manual or automatic cutter.

Who is interested in investing in wood pallet block production?

Customers who invest in Shuliy wood pallet block production line generally fall into two categories:

- Own disposal of leftover wood scraps. This type of customer generally has his own related wood processing plants and wants to use the scraps to generate income.

- Customers who are in the business of producing and selling wood blocks. These customers are specialized in this business.

How to profit by making wooden blocks?

Because the raw material for the production of wood blocks is the wood waste to be discarded, reproducing them is already profitable.

In addition, the produced blocks are widely used in supermarkets and logistics. The commercial sale increases the profit.

Services offered by Shuliy Machinery

- Pre-sale, on-sale & after-sales service

- Pre-sale service

- 24-hour online service

- We can provide you with project design, process design, and a suitable purchase program. Design and manufacture products based on your specific needs.

- On-sale service

- Accompany you to visit our factory, explain the manufacturing process of our machines and check the working performance of our machine.

- After-sales service

- Installation guidance

- Solve problems in time. If you encounter any problems during the use of the machine, please contact us at any time.

- Pre-sale service

- Dispatch engineer to guide the installation

- According to the customer’s requirement, we will dispatch engineers to guide installation and train about the operation of the compressed wood pallet block production line.

- Customization service

- You can send your sample scrap materials to us and we will test the machine for you without charging the fees. And we can customize the machine to meet your production requirements.

If you are interested in the wood pallet block production line, please contact us. We will provide you with the best solution according to your needs.