Compressed Wood Pallet Machine

| Brand | Shuliy |

| Raw materials | Sawdust, wood shavings, rice hulls, fiber(under 1cm), bamboo, coconut shells, palm shells, etc. |

| Wooden pallet sizes | 1000*1000mm, 1100*1100mm, 1200*800mm, 1200*1000mm, etc. |

| Weight of wood pallet | 17-18kg per pallet |

| Applications of wood pallets | Transportation companies, large supermarkets, shopping malls, etc. |

You can now ask our project managers for technical details

Shuliy wood pallet machine is to produce wooden pallets from sawdust, rice husks, coconut shells, etc. by high temperature and pressure. The wooden pallets can be used as load-bearing piers in shipping companies, large supermarkets and shopping centers.

The raw material requires that its moisture content is about 10%. Besides, we can make wooden pallets with common sizes of 1000*1000mm, 1100*1100mm, 1200*800mm and 1200*1000mm. Of course, we can also customize the size to meet your demands.

This compressed wood pallet making machine utilizes waste wood, so it’s a great solution for waste recycling to make profits.

Raw materials of the molded wood pallet machine

When using this wood pallet making machine for waste recycling, you should know which raw materials can help you turn waste into treasure.

The raw materials for making wood pallets are wood scraps, wood chips, wood shavings, rice hulls, fiber(under 1cm), bamboo, coconut shells, palm shells, paper, etc.

Wooden pallet size, usage and weight

The sizes of wooden pallets that can be made from the above materials and their applications are as follows:

- Sizes of wood pallets: our pressed wood taller machine can make common sizes and customized sizes.

- Common sizes: 1000*1000mm, 1100*1100mm, 1200*8000mm, and 1200*1000mm.

- Customized sizes: 600*800mm, etc. We customize the pallet size according to customer needs.

- Application of wooden pallets: transportation companies, large supermarkets, shopping malls, etc. Its role is to carry the weight, facilitating the operation of forklifts.

- Weight: 17-18kg per wood pallet.

Strengths of the wooden pallet machine for sale

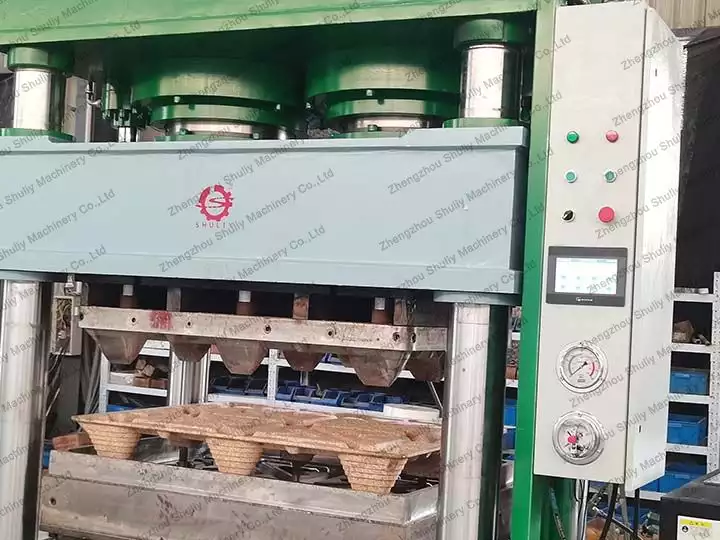

- Four columns solid type: because of this design, the wood pallet machine has good stability when working at high temperatures.

- Pressure: there are two sub-cylinders on both sides of the machine, the role is to help improve the pressure. In this way, the density of the pallet is higher and the quality is better.

- Control panel: through the operation of the control panel, it’s convenient and fast to set control time and temperature.

- Customized moulds: depending on your needs, we can customize the suitable mold for you to make satisfied wooden pallets.

- A wide range of raw materials applied: wood chips, wood shavings, sawdust, rice husks, coconut shells, etc. can be used as raw materials to make wooden pallets.

Technical parameters of the wood pallet making machine

| Model | SL-800 | SL-1000 |

| Power | 7.5kw | 15kw |

| Pressure | 800t | 1000t |

| Capacity | 8pcs per time | one pallet needs 4-5 minutes(you can control by yourself) |

| Dimension | 2.3*1.5*3.5m | 1.9*1.3*4m |

| Weight | 11t | 21t |

| Final pallet size | 1200*1000mm, 1200*800mm | 1200*1000mm, 1200*800mm |

The above parameters are for your reference when choosing the machine.

If want the right equipment, you need to tell us your raw material, the size of the wooden pallet(we provide some sizes for your reference), weight capacity, etc., and our sales manager will provide you with the optimal solution according to your needs.

What is the composition of the automatic wood pallet making machine?

Hydraulic system: it mainly has the hydraulic pump station, providing pressure when the machine works.

Generally speaking, the pressure has 800t, 1000t, 1200t, etc.

The hydraulic cylinder acts on the mold. This makes the produced wooden pallets have high density and good load-bearing capacity.

Control cabinet: control the work of the upper and lower molds.

Molds working section: produce the satisfied wood pallets.

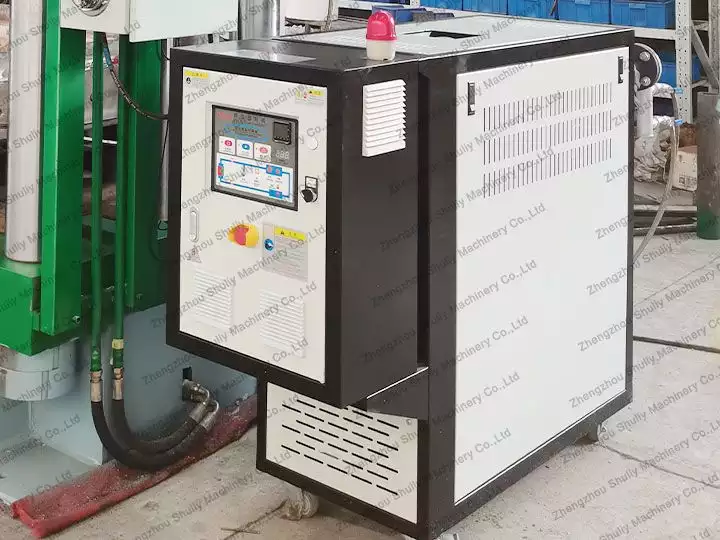

Mold temperature machine: connecting to the mold, it provides high temperature. The temperature is generally 180℃.

Also, it needs heat-conducting oil or a heat-conducting furnace, which generally uses heat-conducting oil.

Working process of the pressed wood pallet machine

With high temperatures and pressure, the waste wood can be formed into quality wooden pallets. The whole process of making wood pallets is shown as follows:

- First of all, the mold needs to be heated to 180℃, then put the raw materials into the middle of the mold. It should be noted that the raw materials need to be laid flat on the top edge.

- Then, start the moulded wood pallet machine. It takes more than 4-5 minutes to make one pallet.

- After finishing, the upper mold rises, and the lower mold ejects the pallet. The complete production process of one wood pallet is completed.

What are the advantages of the wood pallets?

- Import & export: good quality of the produced wooden pallets for sale.

- Fumigation free: the wooden pallets are fumigation free.

- Environmentally friendly: because it is made from recycled trimmings.

- Low water content: the wood pallets are more stable, not easily deformed, and have a long service life.

- Large load capacity: for example, for 1000*1000 pallets, the static load is 5t-10t, and the dynamic load is 3-5t.

- Save space: wooden pallets can be stacked, and the rubber pier of the pallet can be retracted.

Global cases of Shuliy wood pallet hot pressing machine

SL-800 wooden pallet maker machine exported to Mexico

This Mexican customer has his own company and bought the wood pallet machine mainly to process the waste and turn it into treasure for his own use.

Attracted by our machine customization, cost-effectiveness and after-sales service, this customer placed an order for making 1200*1000mm and 600*800mm wooden pallets.

We quickly arranged for production. After completion, we arranged for transportation by sea.

Contact us for more machine details!

We not only provide single equipment, but also have the complete compressed wooden pallet production line for sale to help you realize efficient production. We look forward to cooperating with you and providing high quality service for your waste recycling business.

If you want to know more details about our equipment, welcome to contact us. We will provide you with professional solutions to meet your various needs.