Automatic Compressed Wood Pallet Production Line

| Brand | Shuliy |

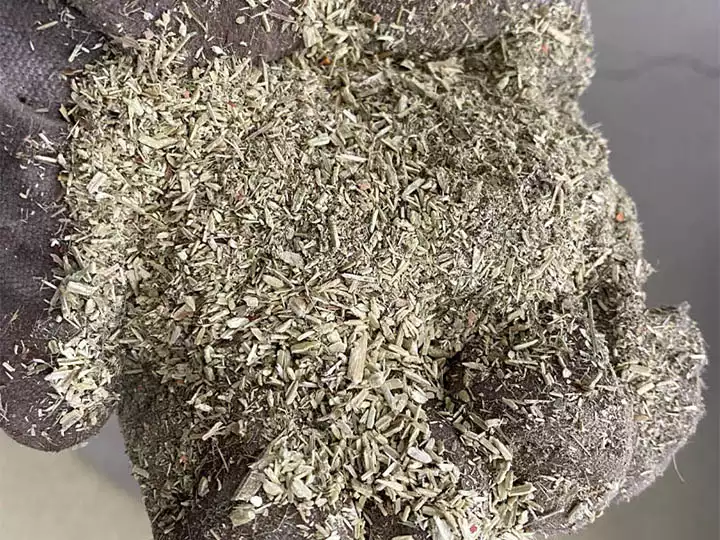

| Raw materials to make wood pallets | Sawdust, wood chips, wood shavings, bamboo, fibers, coconut shells, rice husks, paper, etc. |

| Wooden pallets size | 1000*1000mm, 1100*1100mm, 1200*800mm, 1200*1000mm, also customized. |

| Applications of wood pallets | Shipping companies, supermarkets, shopping malls, etc. |

| Capacity | 220pcs/day |

You can now ask our project managers for technical details

Shuliy’s wood pallet production line is processing sawdust, wood chips, shavings, coconut shells, rice husks, etc. into quality wooden pallets. These wooden pallets are widely used as load-bearing carriers in forwarding companies, supermarkets and shopping centers.

The common sizes of moulded pallets are 1000*1000mm, 1100*1100mm, 1200*800mm, and 1200*1000mm. Also, we can customize the size depending on your needs.

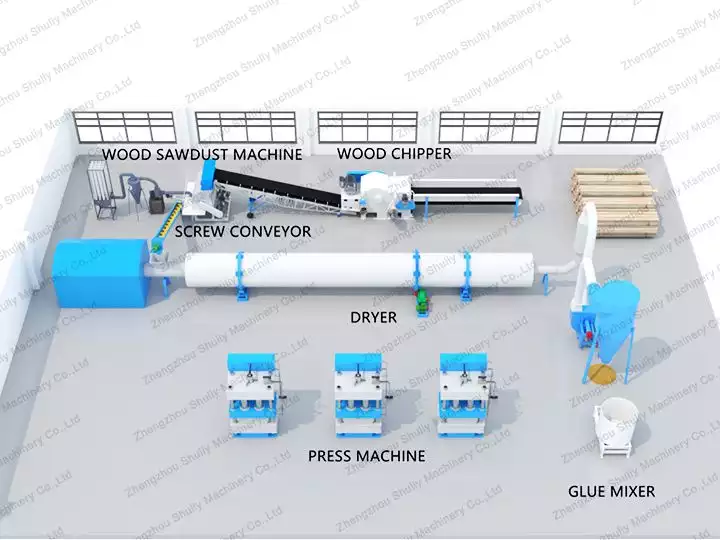

The compressed wood pallet production line includes drum chipper→hammer mill→sawdust dryer→glue mixer→pressed wooden pallet making machine. It’s a great solution for investors to turn waste into treasure.

Why invest in the production of wooden pallets?

The wood pallet is a kind of dragging tray made of purely natural wood.

Because of their cheap price, easy production & processing, and strong application, wooden pallets are widely used in freight logistics transport, container delivery, and other industries.

For those who have waste wood to make a profit, investing in the automatic wood pallet production line is a great choice.

How to make wood pallets?

Want to produce high-quality wooden pallets? Take a look at the production steps below.

Step 1: chipping wood waste into small chips

In order to facilitate subsequent processing, the waste wood should be first divided into uniform wood chips.

The drum wood chipper is applied and the wood chips’ size is adjustable to meet your needs.

Step 2: crushing wood chips into sawdust

To improve the material utilization rate, the wood chips are further crushed into fine wood chips.

The hammer mill for wood can help you complete this step.

Step 3: drying sawdust

Sawdust contains a certain amount of moisture, and the production of wooden pallets requires less than 10% moisture. Therefore a sawdust dryer is needed to reduce the moisture content.

Step 4: mixing glue and sawdust

Then, mix the dried wood sawdust with glue evenly to enhance the strength and durability of the wood pallets.

Step 5: compressed wood pallet making

Finally, the wood pallet making machine is to press mixed sawdust into shape to produce the required wood pallets.

Equipment used in the compressed wood pallet production line

After understanding the workflow, let’s take a look at the specific machine configuration and parameters in the production line.

You can refer to the below table when choosing the wooden pallet making line.

| S/N | Machine name | Machine picture | Specifications |

| 1 | Drum chipper(with the conveyor) |  | Model: SL-216 Capacity: 3-10t/h Power: 55kw Final size: 5cm Dimension: 2735*2200*1200mm Weight: 4t |

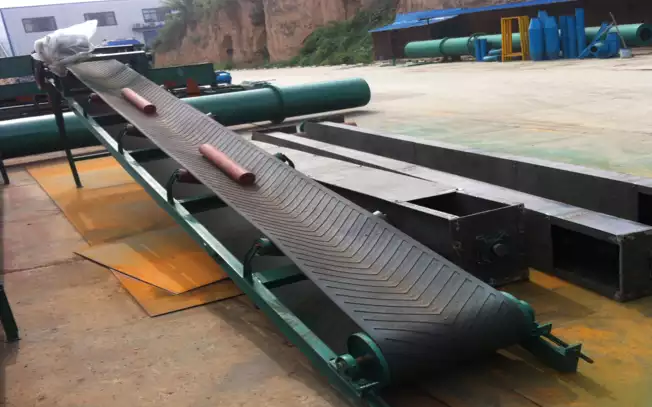

| 2 | Conveyor |  | Length: 6m Width: 60cm |

| 3 | Hammer mill rusher(with cyclone) |  | Model: SL-800 Capacity: 1.5-2tper hour Power: 37-45kw Quantity of blades: 50pcs Dimension: 2.5*1.4*1.5m Weight: 1.5t |

| 4 | Screw feeder |  | Length: 5m |

| 5 | Sawdust dryer(with dust collector part) |  | Model: SL-1000 Power: 13kw Capacity: 3000kg/h Weight: 6t Dimension: 1*10m |

| 6 | Bucket elevator |  | Length: 7-8m |

| 7 | Stock bin |  | Model: SL-LC-40(with discharging conveyor) Volume: 40m³ Size: 5000*3000*4500mm Weight: 4t |

| 8 | Glue mixer |  | Model: SLD-2 Capacity: 1-1.5t/h Power: 5.5kw With electronic weigher and glue spray Size: 6000*1800*3500mm Weight: 3.5t |

| 9 | Thermal oil furnace heated by biomass material(including whole set pipes, boilers, pumps, cabinet, etc.) |  | Model: SGL-350T Rated Power: 350KW Rated thermal pressure: 0.8MPa Rated working temperature: 320℃ Size: 2*2*7m Weight: 6t |

| 10 | Compressed wood pallet machine |  | Model: SL-800-102 with two molds Molds size: 1200*800mm(customizable) Power: 11kw Capacity: 220pcs/day Theoretical pressure: 800t Working pressure: 25MPa Oil cylinder: Φ360*4pcs Stroke: 400mm Dimension: 3.3m*3m*3.2m Weight: 25t |

| 11 | Intelligent electric control cabinet | / | Connect and control the chipper and crusher |

Advantages of compressed wooden pallet production line

- Wide applications of raw materials. To make wood pallets, you can use wood waste, sawdust, wood chips, wood shavings, rice husks, coconut shells, fibers, paper, etc.

- Easy to operate. The whole line is highly automatic. Moreover, our compressed wood pallet making machine is controlled by a control cabinet, and you only need to operate the button.

- Environmental protection and economic benefits. The equipment can effectively utilize wood waste to generate income.

- For the environment, using this line reduces waste existing in nature.

- For investors, the line helps them turn waste into treasure.

Wood pallet molds and sizes

The size of our wooden pallet molds can be customized according to customers’ needs. Whether it is a common size on the market or a size that requires special customization, we can meet it.

Common sizes of wood pallets: 1000*1000mm, 1100*1100mm, 1200*800mm, 1200*1000mm, etc.

When you want to invest in an automatic wood pallet production line, please let us know the size of the wood pallets you want to produce. We will customize the mold and solution for you.

Projects of compressed wood pallet production line

Pressed wooden pallet production line sold to Mexico

One customer from Mexico bought the line to process his company’s waste.

When he bought this wood pallet production line, our sales manager also configured the line to suit his situation. Here are some of the details for your reference.

Wooden pallet machine factory visit from Turkish customers

Turkish customers came to our factory and personally inspected the production process and equipment performance of the wooden pallet production line.

He expressed their satisfaction with the quality and production capacity of our products, and conducted in-depth business negotiations.

Southeast Asian clients visit our pressed wood pallet machine factory

Southeast Asian customers visited our factory, and understood in detail the operation process and technical advantages of the wood pallet machine.

They spoke highly of our professionalism and service attitude, and expressed their willingness for long-term cooperation.

Get in touch with us now!

Interested in wooden pallet production? if yes, come and contact us for more machine details! We’ll design a suitable solution for you to benefit from wood waste.