Drum Chipper | Wood Chipping Machine

| Hot-selling models | SL-218, SL-216 |

| Capacity | 5-15t/h |

| Raw material dimension | 230-500mm |

| Final wood chips size | 25mm(Adjustable) |

| Features | 4 feeding pressure rollers, reinforcement bearing, automatic lifting device, etc. |

| Matched equipment | Wood peeling machine |

You can now ask our project managers for technical details

This drum chipper is to cut logs, branches, boards, waste veneers, bamboo, etc. into regular small wood chips with a size of 25mm(adjustable). It can handle waste wood in mass quantity, and the capacity reaches 5-15t/h.

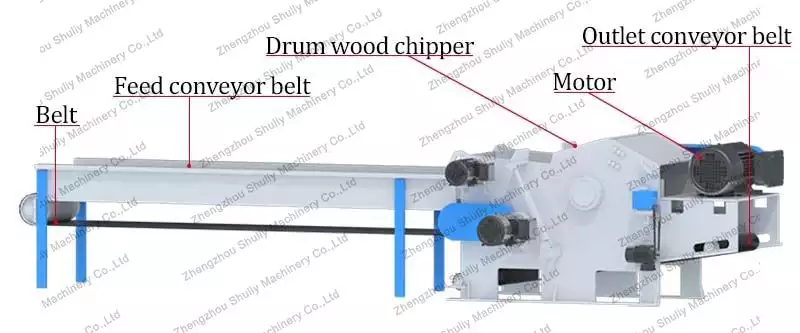

And our machine always works with the conveyor for conveying and automatic wood processing work. The feeding and outlet ports both can use the conveyor for easy work.

Besides, famous for a wide range of applications, good machine performance and long service life, our drum wood chipper is very popular all over the world. It has been exported to Australia, the USA, Germany, Yemen, South Africa, Peru, etc.

Raw materials to be chipped and applications

This wood chipper machine has a wide range of applications on the raw materials, but you should attention that the wood raw materials should be without nails, including but not limited to:

Wood, bamboo, slab, branches, straws, timber, logs, branches, boards, waste veneers, cotton stalks, and other non-wood fiber stems.

After chipping, the wood chips have various usages.

- Raw materials are applied in various industries. Biomass fuel plants, paper making, biomass power plants, pulp, artificial boar, burning fire, wood board plants, compressed board plants, making pellets(as raw materials), and other industries.

- High-quality wood ships for sale. This belongs to creating profits, which benefits your wood business.

In order to better produce quality wood chips, we can use a wood log peeling machine before using a wood chipper.

Besides, this drum chipper can also be used for sawdust production. It is used before the production line as a coarse crushing step, and then deep processing can be carried out.

Features of commercial drum chipper for sale

- New design blade rotor, so the blades are easy to replace.

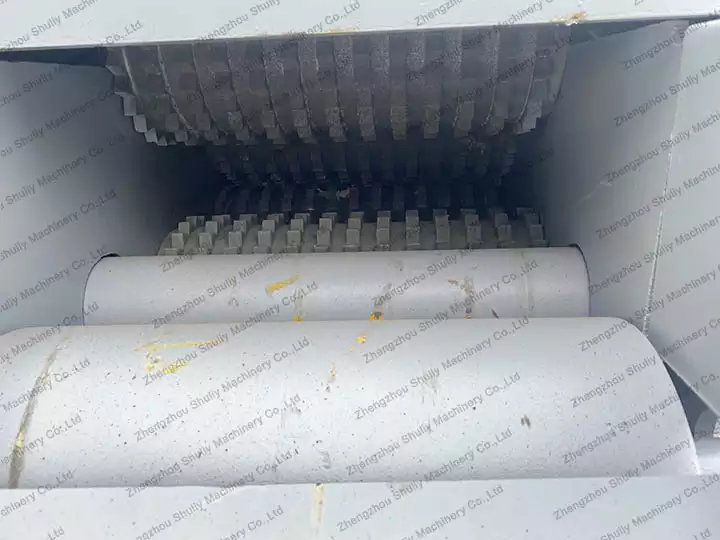

- Equipped with the 4 feeding pressure rollers. Its function is to grasp and bite the wood and force the material to be fed.

- Reinforcement bearing is applied, and durable.

- It has an automatic lifting device(hydraulic system). When feeding, it can automatically recognize the height of the wood and will automatically lift according to the wood.

- Equipped with a separate control cabinet. The control cabinet is necessary so that when using the machine, the electricity is safer.

- This machine can process waste wood with a dia. of 230-500mm, and has a capacity of 5-15t/h. Thus, it’s ideal for wood processing plants.

Technical parameters of the drum wood chipper for sale

| Model | SL-218 | SL-216 |

| Knife quantity | 2 | 2 |

| Feeding size | 300*680 mm | 230*500 mm |

| Capacity | 10-15 t/h | 5-8t/h |

| Raw material dimension | ≤300 mm | ≤230 mm |

| Wood chip size | 25 mm(Adjustable) | 25 mm(Adjustable) |

| Main power | 110 kW | 55 kW |

| Weight | 8600 kg | 5600 kg |

| Feeding inlet conveyor | 6 m | 6 m |

| Outlet conveyor | 8 m | 8 m |

| Packing size | 3105*2300*1650 mm | 2735*2200*1200 mm |

Listed above are our hot-selling models for your reference when you want to do a large amount of waste wood processing.

Construction of the wood drum chipper

Shuliy drum chipper is mainly composed of belt, feeding port, knife plate, motor, internal structure(press roller, blade, and screen), and electric control.

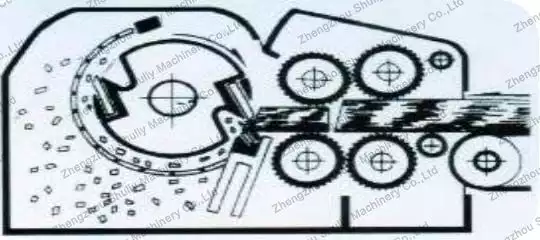

If you want to produce different specifications and thicknesses of wood chips, you can achieve this by adjusting chipping blade quantities.

How does a drum chipper work?

- Feed the wood through the feed inlet, and the roller will catch, press, and push the wood to move forward.

- Then the wood comes to the core part. The blades start to chip the wood into pieces. There is a screen at the bottom of the machine(inside). The screen size decides the size of the chips.

- Finally, the qualified wood chips come out from the screen.

FAQ of drum wood chipper

Q1: Why equip a separate control cabinet when using this large wood chipper?

A1: Because of this, you can use electricity safely when operating the machine.

Q2: Is Shuliy Machinery a manufacturer or distributor?

A2: We’re integrated with the producing and providing. Compared to other trading companies, you can get the best price from us.

Q3: How can I use the machine after receiving it? Is there any manual?

A3: We enclose the manual with the machine. What’s more, we can chat online/via video to help you understand the machine clearly, if necessary.