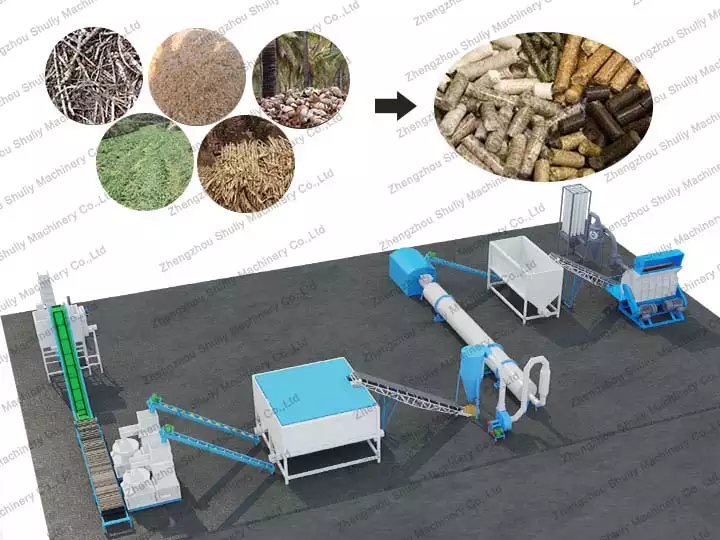

Complete Wood Pellet Production Line for Making Biomass Pellets

biomass wood pellet plant

Capacity: collocation to suit customer requirements

Raw materials: straws, rice husks, sawdust, wood shavings, wood chips, corn stalks, bamboo powder, etc.

Features: high efficiency, great performance, customization

Machine used in the pellet production line: hammer mill, mixer, sawdust drying machine, storage tank, pellet mill machine, cooling tank, package machine, conveyors, etc.

The wood pellet production line is suitable for the production of large or medium-sized wood pellets and is characterized by its high efficiency, good performance, and the possibility of customizing the whole line. The raw materials used for the production of biomass pellets are straw, wood chips, shavings, sawdust, and various shells such as peanut shells, coconut shells, and rice husks.

The wood pellets produced are broadly divided into two uses, one is for animal feed and the other is for various fuels. Whichever is the case, just tell us what you need and our sales manager will outline the best solution for your needs.

Machine list for the complete biomass wood pellet production line

– Crushing of various raw materials to a certain fineness for the next step.

– High efficiency, energy saving, and good performance.

– Can be pulverized to a finer powder, with different screen sizes according to customer needs

Mixer machine

– Stir the ingredients thoroughly so that they are evenly mixed.

– Labour-saving and highly mechanized.

– The mixer can be selected according to the customer’s output.

Drying machine

– Reducing the moisture contained in the raw material in preparation for the next step of granulation.

– The drum dryer allows for a uniform airflow and more even heating.

– Optional heating is steam, gas, and oil.

Biomass pellet mill machine

– Core section, used to produce wood chip pellets.

– The output can be configured according to customer needs.

– Fast production speed and good quality of the wood chip pellets produced.

Cooling machine

– Once the pellets are produced, they will have a certain temperature and if you wait for them to dry naturally at this time, it will take longer, so you need a cooling machine to shorten the process.

– It is often used after the pellet machine, in the second half of the whole wood pellet line.

Packaging machine

– Used in the final step of the complete wood pellet plant line to pack the pellets.

– The packaging range is from 5 to 50 kg, bagged as required and the weight of each bag can be adjusted.

Wood pellets manufacturing process

The process of producing pellets can be divided into four steps in total: the efficient grinding step, the drying step, the pellet extruding step, and the cooling and packaging step.

Grinding – Hammer mill machine: this machine is the main machine to carry out the materials grinding.

Drying – Sawdust drying machine: the machine is to dry raw materials.

Pellet extruding – Pellet mill machine: it’s the key part to produce high-quality biomass wood pellets.

Cooling & packaging – Cooling tank & package machine: the last step is to package the wood pellets into bags.

In these processes, of course, conveyor belts, cyclones, etc. are also used. It’s also suitable for small scale wood pellet production.

What affects the wood pellet production line price?

In fact, the purchase of a pellet production line is influenced by various aspects, which are described below.

- Wood chip pellet mills. There are two types of wood chip pellet mills at Shuliy, the flat die pellet mill and the ring die pellet mill. The price of choosing a different type of machine is of course different.

- Capacity. The configuration of the production line required for the production of wood pellets varies with different yields. The output of the chosen machine will also be very different, which greatly affects the price.

- Raw materials. If your raw material is wood chips, you can use a hammer mill to crush it to get finer sawdust. However, if your raw material is scrap wood, you will need a wood chipper or other corresponding machine.

So, when choosing a wood pellet production line, please let us know your requirements and our professionals will recommend the right machine configuration for you.

Successful projects of the wood pellet production line for sale

Shuliy’s pellet production line is capable of producing pellets of different volumes to meet the different needs of our customers. Since we started selling our wood pellet lines, we have exported them to different countries such as Mexico, El Guado, Indonesia, etc. Below is an example of a wood pellet line sold to Indonesia in 2022 for your reference.