Wood Debarker for Logs Bark Removal

Wood Peeling Machine | Log Debarking Machine

Brand: Shuliy

Types: Vertical & horizontal tree peeling machine

Hot-selling models: SL-250, SL-320, SL-370, SL-420

Tree dia. that can be processed: 50-500mm

Service: After-sales service, customization, spare parts for free(for a certain period)

Warranty: 1 year

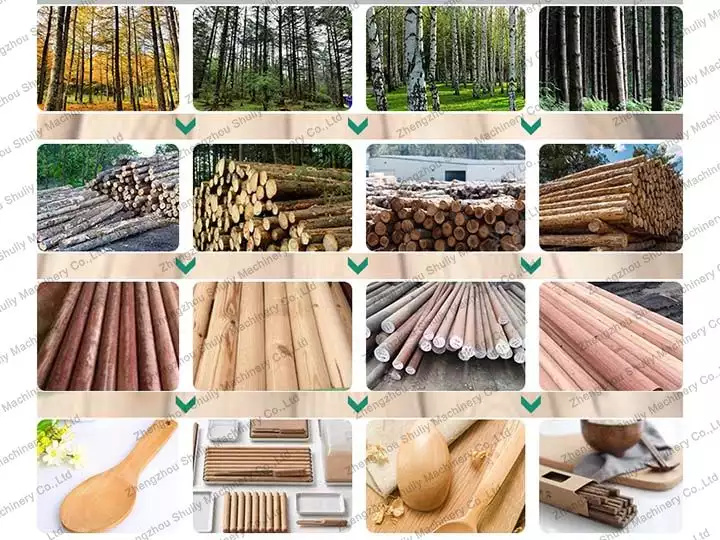

Our wood debarker is to remove tree bark from wood logs(like oak, firewood, Sandalwood, Poplar, etc) with dia. 50-500mm, with a debarking rate of >95%.

Featuring high efficiency and powerful adaptability, we have two types of wood log debarking machines for sale: vertical & roller debarking machines.

Because of its features, our wood debarking machine is widely used in wood processing plants worldwide, such as in the United States, Australia, European countries, South Africa, Thailand, Ukraine, etc.

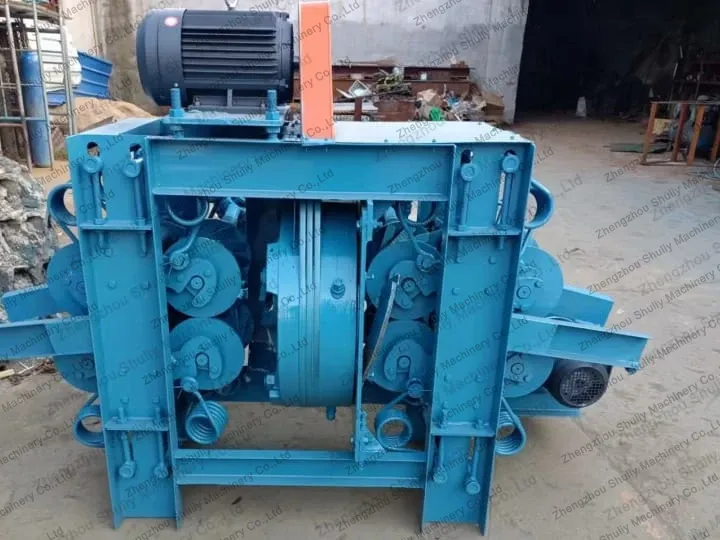

Type 1: Small vertical log debarker

- Suitable wood log dia.: 5-35cm

- Capacity: 10m per minute

- Power system: electric motor or diesel engine

- Matched device: conveyor which is convenient for feeding wood logs

- Unique design: 4-input 4-output rollers

Features of wood debarker

- Customization: voltage, tyres, frame, etc.

- Quality knives: made of 45# steel, the blade is sharper and more wear-resistant.

- Peeling rate of >95%: the friction between the blades debarks the wood cleanly and quickly as it moves.

- Machine made of Q235 steel, more solid frame, long service life.

- The fresher the wood, the better the skinning.

Parameters of portable wood stripper

| Model | SL-250 | SL-320 | SL-370 | SL-420 |

| Capacity | / | 10 meters per minute | 10 meters per minute | 10 meters per minute |

| Power | 7.5 kW+2.2 kW | 7.5 kW+2.2 kW | 11 kW+2.2 kW | 15 kW+4 kW |

| Suitable wood diameter | 50-250 mm | 100-300 mm | 100-350 mm | Max. 400mm |

| Machine size | 1730*2460*1410mm | 1790*2320*1250mm | 2460*1420*1500mm | 2500*1400*2000mm |

| Package weight | 1410 kg | 1450 kg | 1500 kg | 1750 kg |

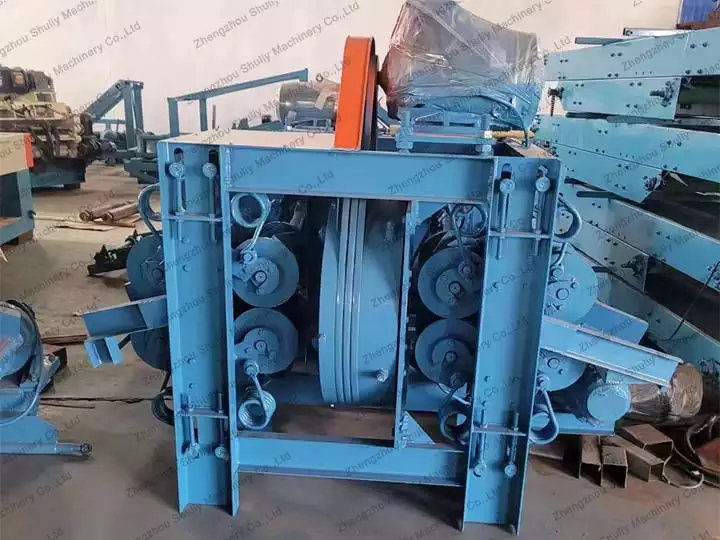

Structure of wood debarker for sale

This ring debarker consists of the feeder, working chamber, outlet, and power system.

The working chamber has a group of ring-shaped cutters and racks, functioning to debark.

In addition, at the feeder and outlet, we can use the conveyor to connect the machine, to facilitate the woods coming and going.

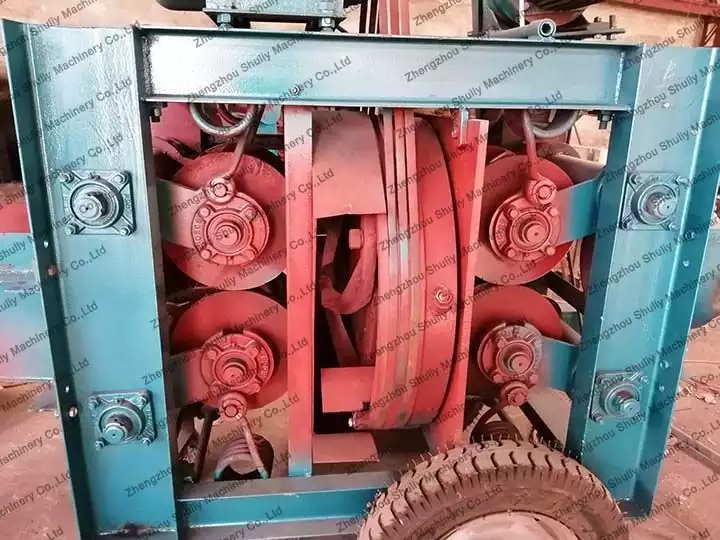

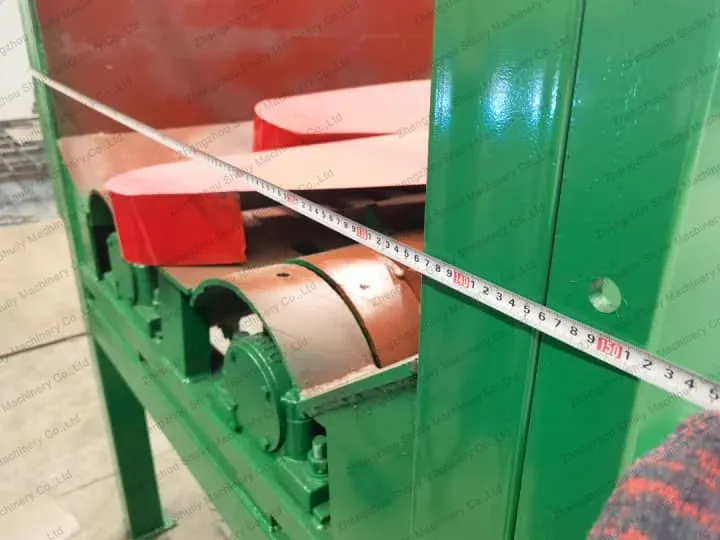

Working principle of small wood log debarker

The below picture shows the core part of the wood log debarking machine when it’s working.

- Place wood horizontally into the bark stripping machine. Start the machine, and the built-in rotating cutter disk or blade starts to rotate at high speed. The blade touches the wood surface to strip off the bark.

- Through the clamping device inside the machine, the wood is continuously rotated under the action of the rotating cutter disk, so that the bark is evenly stripped off.

- The peeled-off bark is discharged through the discharge port, and the peeled wood is conveyed through another discharge port.

The whole process is efficient and continuous, ensuring that the bark is completely removed from the surface of the wood, leaving a smooth surface.

Type 2: Industrial log debarking machine for sale

- Suitable wood logs dia.: ≤25cm

- Capacity: 5-18t/h

- Wood that can be peeled: branches, irregular woods, etc.

- Power system: electric motor

- Matched device: wood chipper, conveyor

Features of wood log debarking machine

- As long as the trees to be barked are between 2-6 meters in length, our machine can handle them.

- Debarking in batches, this machine can debark 5-18 tons of trees in an hour, ideal for large quantities of wood processing.

- We can customize the machine size and roller according to the customer’s requirements.

Parameters of commercial wood peeling machine

| Model | SL-S500 | SL-S600 | SL-S700 | SL-S800 |

| Wood diameter(mm) | 50-200 | 50-300 | 50-400 | 50-500 |

| Wood length(m) | 2-4 | 2-5 | 2-5 | 2-6 |

| Capacity(T/H) | 5-6 | 6-8 | 10-12 | 15-18 |

| Peeling rate | >95% | >95% | >95% | >95% |

| Roller diameter(mm) | 250 | 274 | 370 | 540 |

| Roller rotational speed(rpm) | 230 | 230 | 200 | 180 |

| Roller length(mm) | 580 | 580 | 580 | 580 |

| Power(kW) | 7.5*2 | 7.5*2 | 11*2 | 15*2 |

| Weight(T) | 2.5 | 2.8 | 3.5 | 6 |

| Size(L*W*H)(m) | 6*2.1*1.5 | 6.02*2.26*1.52 | 6*2.5*1.6 | 6*2.8*1.7 |

Structure of commercial wood log debarker

In terms of shape, the double roller wood debarker is different from the ring debarker. This roller debarker has a U-shaped trough, generally equipped with two rollers. The roller diameter changes along with the wood. Of course, the capacity also varies.

Pay attention, there are holes in the U-shaped groove. When working, the impurities will drop through these holes. Therefore, it increases working efficiency, avoiding manual cleaning.

Working principle of wood debarking machine

The debarking machine utilizes debarking rollers to make wood section move in the groove and simultaneously rotate around the axis of the wood section itself, and jump irregularly.

At this time, the continuous friction and collision between the wood section and the roller, and between the wood sections, causes the bark to separate rapidly, and achieves the debarking effect.

Applications of wood log debarking machine

This wood debarker has a large usage because of its debarking characteristics.

- For wood peeling: The log peeler can be used for wood, log, lumps, branches, wooden sections, etc. It has a good peeling effect on frozen wood, bending wood, school tree, Quercus, elm, and other hard-to-peel species.

- For plants using: Shuliy wood peeling machine is suitable for large, medium, and small paper mills, pulp mills, wood chip mills, wood processing plants, forestry plants, wood storage yards, and artificial board plants (such as plywood plants, MDF plants, etc.)

Why choose Shuliy as wood debarking machine supplier?

As a professional and leading wood machinery manufacturer and supplier, Shuliy Machinery is the first choice of many woodworking factories because of the following advantages:

- Rich experience: We are able to continuously optimize our products according to market demand and customer feedback to ensure the most suitable solutions.

- Variety of wood machinery: Wood debarking machine, wood chipper, sawmill, wood crusher, wood shaving machine, etc., which can meet the diversified needs of different customers.

- Personalized customized service: According to the specific needs of customers, the equipment is customized to ensure that each machine can perfectly match the customer’s production requirements.

- Competitive price: We ensure product quality at the same time, try to reduce production costs, to provide customers with cost-effective products at competitive prices, to help customers save costs.

- High-quality after-sales service: Equipment installation, commissioning, training and maintenance, etc., to ensure that customers can use the equipment smoothly after purchase.

- Global customer trust: Our debarking machines are exported all over the world, such as Thailand, Indonesia, and are widely recognized and trusted.

Successful cases of wood log debarking machine

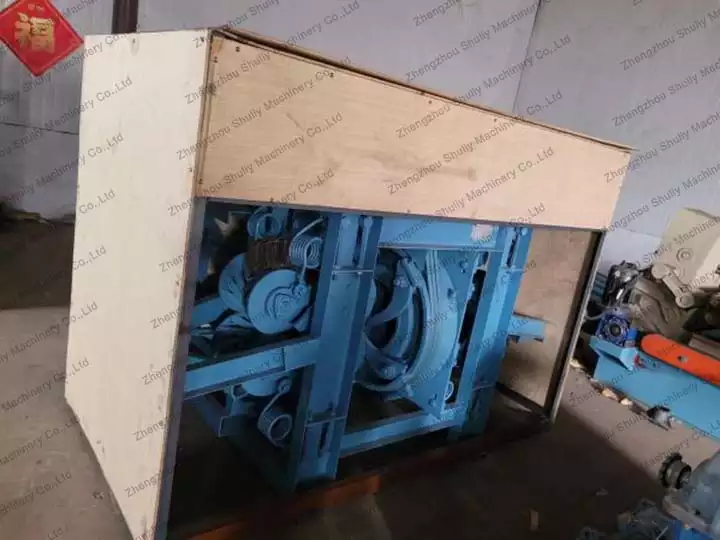

Pine log debarker exported to Thailand

A customer from Thailand has a lumber mill and wanted to wood debarker for further process. He was attracted by our machine’s big tyres, high efficiency and affordable price, and placed the order.

We packaged the machine and sent the machine to his destination. After receiving the machine, he was so happy and satisfied with its working effects.

Vertical wood debarker machine sold to Turkey

A customer from a large local wood processing plant in Turkey wanted more efficient wood processing for the production of construction timber and furniture materials.

Our equipment has the advantages of efficient peeling, easy operation, low maintenance cost, etc., which can greatly improve the efficiency of wood processing and reduce labor intensity, so we purchased our equipment.

Large-capacity wood log debarking machine sold to Indonesia

A new wood processing company in Indonesia lacked equipment that could efficiently peel wood of various sizes, and wanted to improve the efficiency of wood processing and the quality of its products by introducing advanced machinery and equipment.

- The equipment utilizes advanced peeling technology to remove wood skin quickly and evenly.

- It is suitable for different sizes and shapes of wood. In addition,

- Simple to operate and easy to maintain, which is ideal for the customer’s needs.

Eventually, we reached a partnership.

How to place the order?

- Contact and leave your information(including name, WhatsApp, email, and required machine name).

- Discuss machine details with our professional sales manager.

- Determine the machine type and sign a contract.

- Pay a deposit and start machine production.

- Complete machine production and pay balance.

- Arrange goods delivery to your destination.

- Recice machine and start to use it.

FAQ of wood debarking machine

Q1: What kind of wood materials can be handled?

A1: Large pieces of wood, logs, branches, and irregularly curved wood, but also suitable for debarking some frozen and dry wood.

If you have doubts, welcome to inquire!

Q2: What are the advantages of the wood debarker?

A2: Wide applications, durable materials, good debarking effects, high efficiency, and environmental protection.

Q3: Is it conveneint to transport?

A3: Of course, yes.

We are located in Henan Province, China, with very convenient transportation by sea, land, and air. You can choose what you need based on your needs.