Drum wood chipper design highlights

The drum wood chipper design is constantly updated and upgraded to meet the needs of the market and the majority of customers, making it more convenient and efficient to use.

The following are some highlights of the drum wood chipper, hope you will understand and like our machine more and take it as your first choice for wood chipping.

Large feed size – special drum wood chipper design

The feed opening size of this type of wood chipper machine is generally larger, which is suitable for chipping raw materials such as board veneer, edge strip, broken veneer, small diameter wood, and scattered branches into wood chips.

So, the drum chipper is still widely used in fiberboard production and particle board production.

It should not be mistaken that the size of the feed opening is as big as the cross-section of the logs, otherwise, it will damage the blade and the machine.

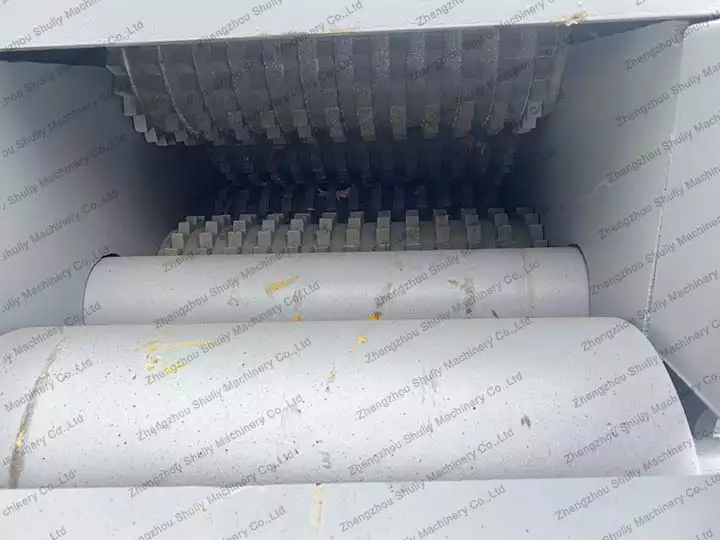

Feeding roller – a good helper to feed various size wood

The drum wood chipper design lies in the forced feeding, regardless of the size of the trees, as long as it is applicable to this machine, can be automatically forced to feed, and finally achieve the purpose of chipping.

Of course, we must pay attention to the trees that are suitable for the current machine, otherwise, the machine will be damaged and the loss will not be worth it.

High-quality material to manufacture – strong & wear-resistant

The overall design of this drum wood chipper is very beautiful, and it is made of high-quality material, which makes the machine durable.

Therefore, this machine not only has a high value but also a very good performance. If you are interested, please feel free to contact us!