What affects the wood debarking machine cost?

With the development of the wood processing industry, the demand for wood debarker machines is growing, and one of the most concerning issues when customers are buying is the price.

The wood debarking machine cost is affected by a variety of factors, and the following are a few key points to determine the cost. Let’s explore it together.

Processing diameter and capacity requirements

If you process larger logs and want a higher capacity, then you require a higher motor, and the wood debarking machine cost naturally rises. Large-capacity equipment is suitable for large-scale processing plants. The initial investment is higher, but the efficiency is better.

Shuliy has a wide range of wood log debarking machines that can handle wood diameters from 50-500mm, 10 meters per minute. For more information, contact us at any time!

Drive mode

The wood peeling machine is usually divided into electric type, diesel engine type and pto model.

- Electric model: suitable for fixed workplaces with sufficient electricity, stable operation and easy to operate.

- Diesel model: suitable for no electricity or field environment, flexible and independent operation ability.

- PTO model: relying on tractor drive, saving power equipment, suitable for agriculture and forestry users.

We have these 3 types of wood debarkers for your choice, and also can customize it to fit your needs.

Degree of automation

The equipment can be equipped with a manual feeding system or an automatic feeding system. The higher the degree of automation, the more labor-saving the operation, the higher the efficiency, but the manufacturing cost is also higher. It’s suitable for the pursuit of labor-saving in medium and large-scale factories.

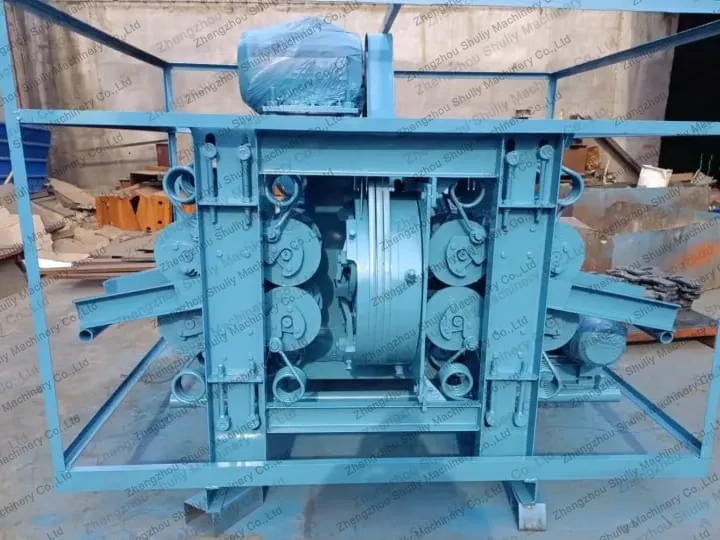

Material and manufacturing process

The equipment durability is determined by a variety of components, including blade material, steel thickness, drive shafts, bearing quality, and so on. High-quality materials, although more expensive, can extend the machine’s life, reduce the failure rate, and provide better cost performance.

Supporting services

Whether the wood peeler includes transportation, installation guidance, operation training, after-sales service, etc., will also affect the overall wood debarking machine cost. Shuliy provides full-process service support to ensure that customers have no worries about the purchase of the machine and long-term operational stability.

Summary

Shuliy wood stripping machine can not only look at the price itself, but also consider the use of demand and long-term return. For detailed models and quotations, please contact us for more details about your wood processing!