Disc Chipper for wood log chips making

| Brand | Shuliy |

| Capacity | 500-8000kg/h |

| Final products' size | 2-5cm |

| Power system | Electric motor or diesel engine |

| Raw materials to be chipped | Wood waste, logs, bamboo, branches, wood segments, etc. |

| Customizable machine shapes | Machine with big tyres, outlet with conveyor, enlarged outlet, lower inlet, etc. |

You can now ask our project managers for technical details

Our disc chipper is to process logs, bamboo, lumber, etc. into regular wood chips(2-5cm) with a capacity of 500-8000kg/h. The wood chips can be used as fuel, paper making, board making, etc.

This wood chipper machine can use electric motor or diesel engine as the power system to work. Also, it has various shapes to meet different demands, such as enlarged outlet, outlet with conveyor, etc.

Besides, this disc style wood chipper has high output, simple structure and advantageous price, thus it’s well received in the wood processing industry.

Raw materials to be chipped and applications

Shuliy wood chips making machine has a wide range of applications. What kind of raw materials can be chipped?

Raw materials include logs, branches, wood segments, templates, some discarded wood, bamboo, lumber, pipe, leather materials, maidenwood, small-diameter wood, etc.

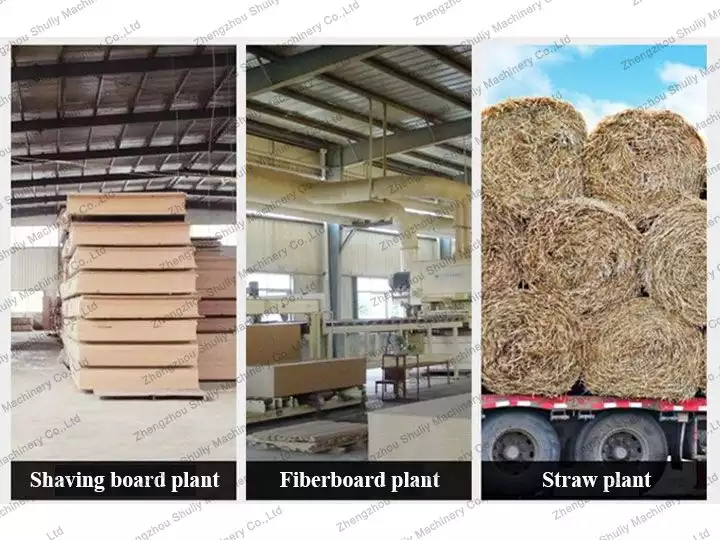

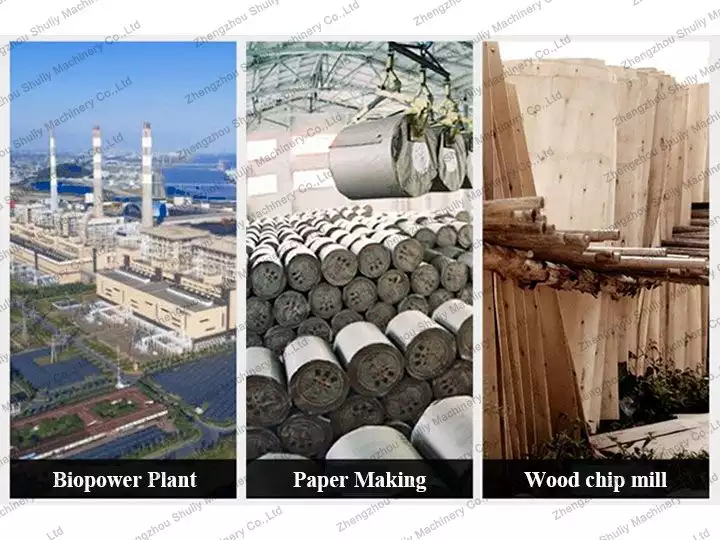

Our disc wood chipper can make log chips with uniform length, flat cut, and even thickness. These wood chips are widely used in shaving board plants, fiberboard plants, straw plants, biopower plants, paper mills, wood chip mills, etc.

Advantages of disc wood chipper

- Simple structure and easy operation. Our log chipper has a compact arrangement(inlet, outlet and interior), easy to understand. And when operating, only start power. One laborer can operate it easily.

- Various raw materials can be chipped. This machine can chip wood, bamboo, thatch, corn stalks, sorghum stalks, and other fibrous culm-like materials.

- Output of 500-8000kg/h. Shuliy small wood chipper can produce wood chips with 500-8000kg per hour, which can handle waste wood quickly and is very high yielding.

- Wide applications of log chips. The wood chips can be as fuel for the power plant, for sale, for paper making, for front preparation for wood charcoal making, etc.

- Adjustable length of wood chips. When cutting logs, the length of wood chips can be adjusted within the specified range by adjusting the length of the blade extension.

Technical specifications of disc chipper for sale

| Model | Capacity | Input size | Output size | Power |

| SL-420 | 500kg/h | 150*150mm | 2-5cm | 11kW motor or 15hp diesel engine |

| SL-600 | 1500kg/h | 180*150mm | 2-5cm | 18.5kW motor or 22hp diesel engine |

| SL-800 | 3000kg/h | 200*200mm | 2-5cm | 30kW motor or 40hp diesel engine |

| SL-950 | 4000kg/h | 230*250mm | 2-5cm | 37kW motor or 60hp diesel engine |

| SL-1200 | 5000kg/h | 330*300mm | 2-5cm | 55kW motor |

| SL-1400 | 7000-8000kg/h | 400*400mm | 2-5cm | 90kW motor |

From the above table, it’s clear that our disc chipper has a wide range of capacity of 500-8000kg per hour. Besides, our machine can use electric motor or diesel engine, which offers multiple options for you.

When you choose a suitable wood disc chipper, pay attention to input size and output size. Each model has corresponding sizes. You can choose a suitable one based on your raw material’s size.

What is the disc chipper design?

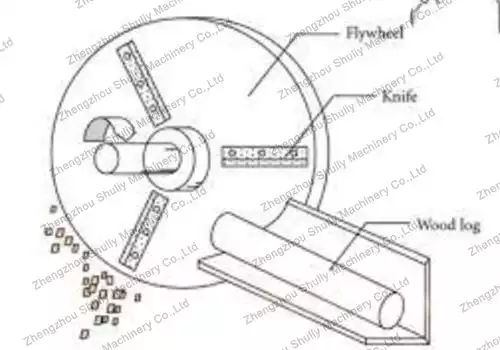

The commercial wood chipper has a simple structure. It has inlet, outlet and internal structure.

- Inlet: multiple inlet sizes enable easy feeding of large pieces of wood or wood waste into the machine. The feeding process can be done manually or by automated devices, ensuring continuous and efficient work.

- Outlet: it’s responsible for discharging the processed wood chips. The outlet is usually equipped with a conveyor belt that allows the finished chips to be transported to a designated location for further processing or packaging.

- Internal structure: the internal part is the key part, including the flywheel and blade.

- The flywheel provides strong kinetic energy to the blades, enabling them to rotate at high speeds.

- The blades are driven by the flywheel to cut through the wood at very high speeds, chipping it into uniform pieces.

How does a disc chipper work?

- Firstly, wood logs or wood waste enter the disc wood chipper through the feed opening.

- Next, the wood enters the machine interior. The wood is fed to a rotating flywheel and blade system. The flywheel rotates at high speed driven by a motor, which drives the blades to cut the wood. Under the high-speed rotation of the flywheel and blades, the wood is cut into uniform pieces.

- Finally, the finished chips are discharged through an outlet. The outlet is usually equipped with a conveyor belt or other conveying equipment to transport the wood chips to a collection unit or the next step in the process.

Various types of disc chippers for sale

As a professional wood machine manufacturer and supplier, our wood chippers have different shapes to meet different demands.

The machine shapes have different types, such as the machine with big tyres, frame, outlet with conveyor, enlarged outlet, lower inlet, etc.

Whatever your needs, tell us and we will provide you with customized solutions.

Successful cases of industrial wood chipper

Industrial log chipper sold to Germany

A customer from Germany wanted a wood chipper to make wood chips and sell them.

When he contacted us, we recommended this disc chipper to him. After reading relevant machine information, the German customer was very satisfied with the machine and asked for a trial run. Our sales manager came to the factory for a test run, with a video link throughout.

After observing the effect of the machine, the German customer immediately placed an order. We finally shipped the machine by sea to his country.

Contact us for wood chipper price!

Are you looking for cost-effective wood processing equipment to produce wood chips? In addition to the disc chipper, we also have the drum wood chipper for you to choose from.

If interested, contact us now and we will provide you with professional solutions according to your needs.